Researchers have developed a metallic gel with high electrical conductivity that can be used to print three-dimensional (3D) solid objects at room temperature. The article “Metal gels for conductive 3D and 4D printing” was published in the magazine Subject.

“3D printing has revolutionized manufacturing, but we don’t know of any prior technology that allows us to print three-dimensional metal objects at room temperature in a single step,” says Michael Dickey, co-author of the paper on the study. Camille. & Henry Dreyfuss, professor of chemistry and biomolecular engineering at North Carolina State University. “This opens the door to the manufacture of a wide variety of electronic components and devices.”

The researchers start with a solution of micron-sized copper particles suspended in water to form the metal gel. The researchers then add a small amount of an indium-gallium alloy, which is a liquid metal at room temperature. The resulting mixture is then mixed. When the mixture is stirred, the liquid metal and copper particles stick together, forming a metallic gel “web” in the aqueous solution.

“This gel-like consistency is important because it means that the copper particles are distributed fairly evenly throughout the material,” says Dickey. “It does two things. First, it means that the particle network connects to form electrical paths. Second, it means that copper particles don’t precipitate in the solution and clog the printer.”

The resulting gel can be printed using a conventional 3D printing nozzle and retains its shape when printed. And if you let it dry at room temperature, the resulting 3D object will retain its shape and become even stronger.

However, some interesting things can happen if users choose to heat the printed object while drying. The researchers found that particle alignment affects the drying of the material.

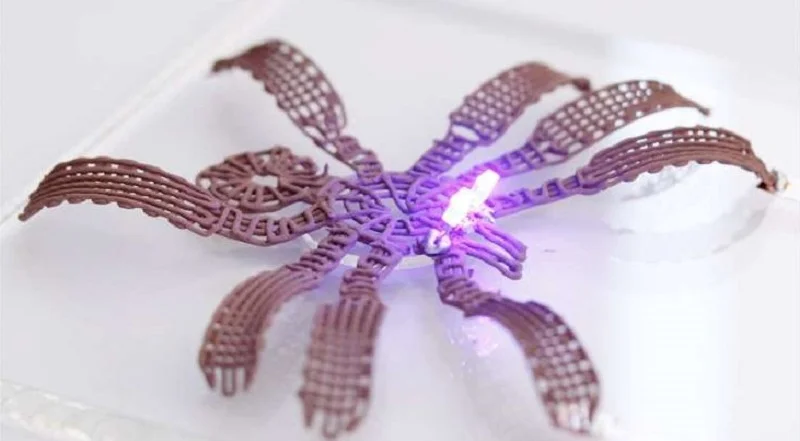

For example, if you printed a cylindrical object, the edges shrink more than the top and bottom during drying. If something dries at room temperature, the process is too slow to cause structural changes to the object. However, if you heat it by placing it under a heat lamp, for example at 80°C, rapid drying can cause structural deformation. Because this deformation is predictable, it means that by controlling the pattern of the printed object and the amount of heat the object is exposed to during drying, you can make the printed object deform after printing.

“Ultimately, this type of four-dimensional printing – traditional three dimensions plus time – is another tool that can be used to create structures of the right size,” Dickey says. “But the most important thing about this material is its conductivity.

“Because printed objects are 97.5% metal, their conductivity is high. Frankly, it’s not as conductive as regular copper wire, but it’s impossible to 3D print copper wire at room temperature. And what we’ve developed is much more conductive than anything that can be printed. We love the applications here.

“We are open to working with industry partners to explore potential applications and are always happy to talk to potential collaborators about future research directions,” Dickey says. Source