Perovskite elements reach an efficiency of almost 25%

- April 2, 2024

- 0

The world of solar energy is ready for a revolution. Scientists are trying to develop a new type of solar cell using materials that can convert electricity more

The world of solar energy is ready for a revolution. Scientists are trying to develop a new type of solar cell using materials that can convert electricity more

The world of solar energy is ready for a revolution. Scientists are trying to develop a new type of solar cell using materials that can convert electricity more efficiently than existing panels.

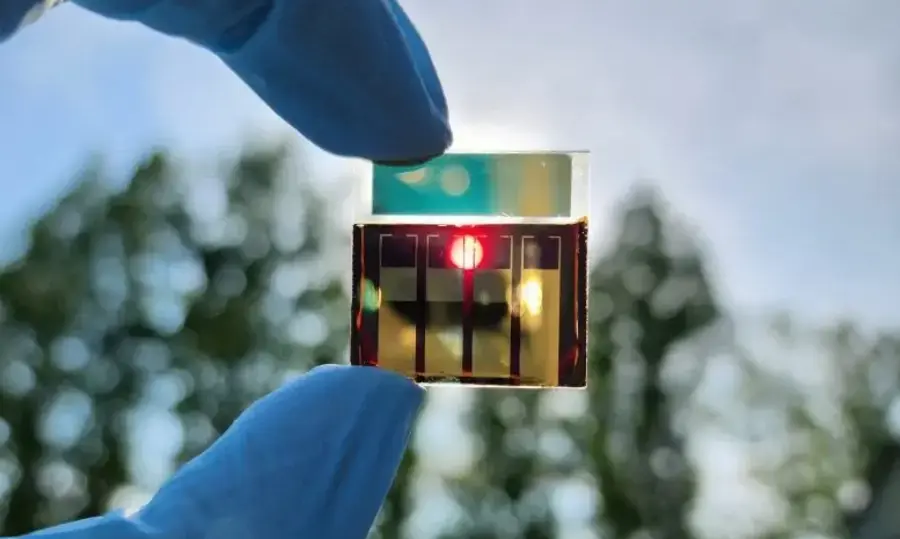

In a new article published in the journal Nature EnergyA researcher from the University of Colorado Boulder and his international collaborators have unveiled an innovative method for producing new solar cells known as perovskite cells; This is a critical advance in commercializing what many consider the next generation of cells. solar technologies.

Today, almost all solar panels are produced from silicon and their efficiency is 22%. This means that silicon panels can convert about one-fifth of solar energy into electricity because the material absorbs only a limited fraction of the wavelengths of sunlight. Silicon production is also expensive and energy intensive.

Enter perovskite. A synthetic semiconductor material can convert much more solar energy than silicon at a lower production cost.

“Perovskites could be a game changer,” said Michael McGehee, a professor in the Department of Chemical and Biological Engineering and faculty member at the CU Boulder Renewable and Sustainable Energy Institute.

Scientists tested perovskite solar cells by stacking them on top of traditional silicon cells to create tandem cells. Layering two materials, each absorbing a different part of the solar spectrum, could potentially increase the efficiency of panels by more than 50%.

“We are still seeing rapid electrification where more cars are running without electricity. “We hope to phase out more coal-fired power plants and eventually get rid of natural gas-fired plants,” McGehee said. “If you believe we will have an all-renewable future, then you project the wind and solar markets to grow at least five to ten times what they are now.”

To achieve this, the industry must improve the efficiency of solar cells, he said.

However, the main problem in producing them from perovskite on an industrial scale is the process of applying the semiconductor to glass plates, which are the building blocks of the panels. Currently, the coating process must be carried out in a small box filled with a non-reactive gas such as nitrogen to prevent perovskites from reacting with oxygen and reducing their performance.

“This is normal in the research phase. But when you start coating large pieces of glass, it becomes increasingly difficult to do this in a nitrogen-filled box,” McGehee said.

McGehee and his colleagues set out to find a way to prevent this harmful reaction with air. They found that adding dimethylammonium formate, or DMAFo, to the perovskite solution before coating could prevent the materials from oxidizing. This opening allows the coating to be applied outside the small box, in ambient air. Experiments have shown that perovskite cells made with the DMAFo additive can achieve an efficiency of approximately 25% on their own; This compares with the current efficiency record of 26% for perovskite cells.

The supplement also improved cell stability.

Commercial silicon panels can generally retain at least 80% of their performance after 25 years, with an efficiency loss of approximately 1% per year. However, perovskite cells are more reactive and decompose faster in air. A new study found that a perovskite cell made with DMAFo retained 90% of its efficiency after researchers exposed them to sunlight-mimicking LED light for 700 hours. In contrast, cells formed in air without DMAFo rapidly degraded after only 300 h.

He noted that although this was a very encouraging result, it was 8,000 hours per year. Therefore, longer tests are needed to determine how these cells hold up over time.

“It’s too early to say they’ll be as durable as silicon panels, but we’re well on our way to getting there,” McGehee said.

The research brings perovskite solar cells one step closer to commercialization. At the same time, McGehee’s team is actively developing tandem cells with over 30% efficiency that have the same lifespan as silicon panels in the real world.

McGehee leads an American academic-industry partnership called Tandems for Efficient and Advanced Modules Using Ultrastable Perovskites (TEAMUP). The consortium, along with researchers from three other universities, two companies and a national laboratory, received $9 million from the U.S. Department of Energy last year to develop stable tandem perovskites that can be used in the real world and are commercially viable. The aim is to create a tandem that is more efficient than traditional silicon panels and equally durable for 25 years.

With higher efficiency and potentially lower cost, these tandem cells could have broader applications than current silicon panels, including possible installation on the roofs of electric vehicles. They can add 15 to 25 miles of range per day to a car left in the sun; This will be enough to meet the daily commute needs of many people. Drones and sailboats can also be powered by these panels.

After a decade of perovskite research, engineers have built perovskite cells that are as efficient as silicon cells invented 70 years ago, McGehee said. “We are taking perovskites to the finish line. If tandems work well, they definitely have the potential to dominate the market and become the next generation of solar cells,” he said.

Source: Port Altele

As an experienced journalist and author, Mary has been reporting on the latest news and trends for over 5 years. With a passion for uncovering the stories behind the headlines, Mary has earned a reputation as a trusted voice in the world of journalism. Her writing style is insightful, engaging and thought-provoking, as she takes a deep dive into the most pressing issues of our time.