NASA’s internal watchdog has slammed Boeing’s work on the next version of its space launch system, finding serious flaws in quality control. In a report released Aug. 8, NASA’s Office of Inspector General (OIG) said there were significant problems with Boeing’s work on the SLS Block 1B version at its Michoud Assembly Facility in New Orleans, citing a lack of an acceptable quality management system and a trained workforce.

NASA used the Defense Contract Management Agency (DCMA) to monitor Boeing’s work on the SLS core and booster stages at Misha. “According to DCMA officials, Boeing’s process for resolving contractual nonconformances was ineffective, and the company was often unresponsive to taking corrective action when the same quality control issues recurred,” the OIG report said.

The report found that DCMA issued 71 corrective action requests for Boeing SLS operations at Misha between September 2021 and September 2023. A CAR identifies a specific nonconformance in a work contract. Of the 71, 24 were Level 2 CARs, the more severe versions used for issues that cannot be fixed on the spot or involve safety-critical equipment.

According to DCMA, this CAR number is unusually high for a spaceflight program at this stage of development. One type of CAR — a performance check called a “seal assurance” — was sufficient, and NASA recommended that DCMA develop a Level 3 CAR reserved for serious noncompliance. This CAR was never published because NASA elected to use what the report calls “alternative corrective action methods” that include additional reviews.

The report attributes much of the quality issues to a lack of trained labor. “Michoud officials noted that attracting and retaining a contractor workforce with aerospace manufacturing experience has been difficult, in part due to Michoud’s geographic location in New Orleans, Louisiana, and lower employee wages compared to other aerospace competitors,” the statement said.

The OIG report said it found firsthand evidence of a problem stemming from an inadequately trained workforce. During a site visit in April 2023, OIG officials saw a section of a liquid oxygen tank intended for use in the SLS core stage for Artemis 3 that had been “separated and awaiting disposal” due to welds that did not meet specifications. NASA officials told the OIG that “the weld problems were due to the inexperience of Boeing technicians and inadequate work order planning and supervision.”

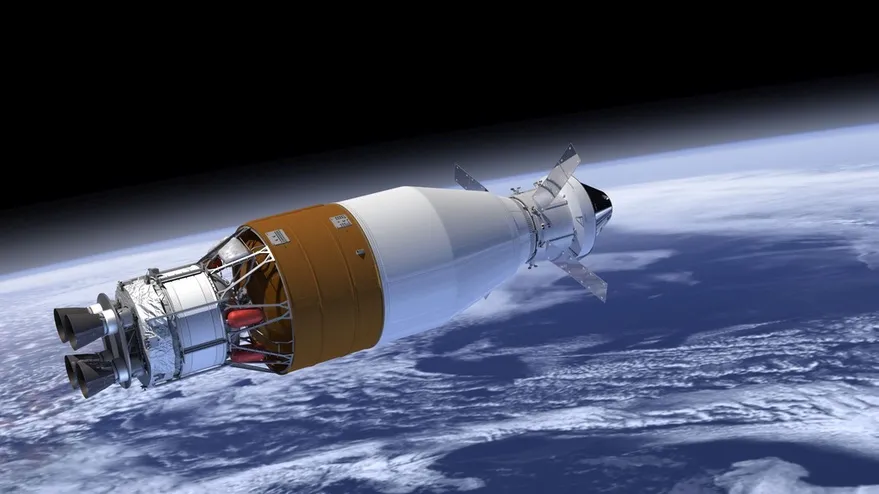

The report also criticized the management of the Exploration Upper Stage (EUS), a key part of SLS Unit 1B that will replace the intermediate cryogenic upper stage used in the original SLS Unit 1. The EUS accounts for more than half of Unit 1B’s $5.7 billion development cost, which has increased by $700 million since the agency committed to the base cost and schedule last December.

While NASA anticipates that EUS costs will decline as Boeing withdraws workers from the project, the report concluded that “we anticipate annual Unit 1B costs will remain at 2023 levels through at least 2026, with declines in subsequent years.” The budget projections do not include additional funding to operate EUS through 2027. This risks delaying the launch of Artemis 4, which is scheduled for late 2028.

Boeing, meanwhile, uses a software tool called the earned value management system (EVMS) that measures progress based on technical, cost, and other data, and has been rejected by the Department of Defense since 2020 due to various flaws. “According to NASA contracting officers, Boeing is unable to establish a realistic baseline delivery date for EUS due to ongoing deficiencies in its EVMS,” the OIG report said.

The report concluded: “Given Boeing’s quality management and related workforce issues, we are concerned about these factors potentially affecting the safety of SLS and Orion spacecraft, including crew and cargo.” It made four recommendations, including an improved quality management program, cost overrun analysis, and coordination with DCMA to bring EVMS into compliance, which NASA adopted in its response.

But the agency rejected a fourth proposal that would have imposed financial penalties on Boeing for failing to maintain quality control. “NASA interprets this proposal as directing NASA to impose penalties outside of the contract,” Kathy Kerner, NASA’s associate administrator for research systems development, said in the agency’s response to the report.

He argued that there were other mechanisms, such as copyright clauses in the contract, that could be used to resolve quality issues. “Implementing financial sanctions outside the contract undermines the process of monitoring the contract,” he concluded.

“Our recommendation is written to permit the Agency to use the most appropriate mechanisms to impose financial sanctions on Boeing for its failure to meet required quality control standards,” the OIG said in the report, acknowledging that the recommendation “pends further negotiations with the Agency.”