New technology makes it easier to create content that defies common sense

- August 21, 2024

- 0

Imagine pulling on the long ends of a rectangular piece of rubber. It should become narrower and thinner. What if it becomes wider and thicker? Now press on

Imagine pulling on the long ends of a rectangular piece of rubber. It should become narrower and thinner. What if it becomes wider and thicker? Now press on

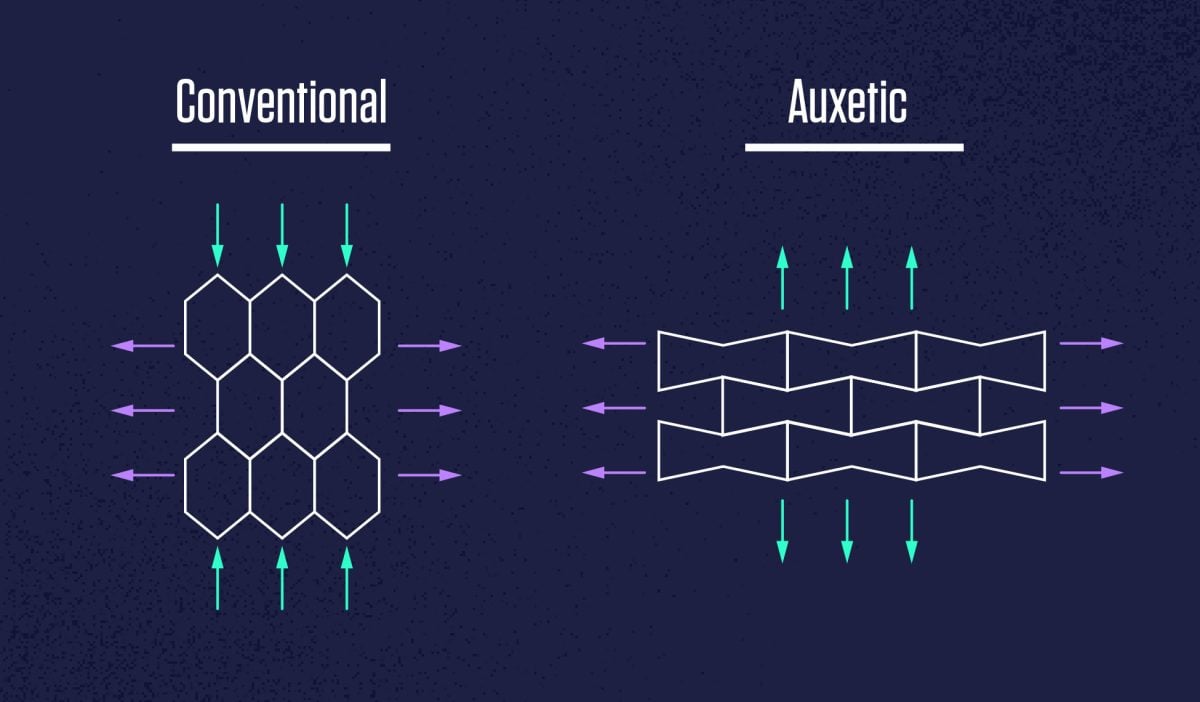

Imagine pulling on the long ends of a rectangular piece of rubber. It should become narrower and thinner. What if it becomes wider and thicker? Now press on the same ends. What if the rubber becomes narrower and thinner?

Such counterintuitive materials do exist. They are called excipients and have a number of unique properties that make them suitable for making shoe soles, bomb-proof buildings, car bumpers and clothing.

Despite this huge potential, auxetic products have been slow to come to market. Researchers at the National Institute of Standards and Technology (NIST) and the University of Chicago hope to change that.

In a new study published in the journal NPJ Computational Materials, they announced the development of a new tool that makes it easier and faster to design materials with auxetic properties. The tool’s algorithm allows for accurate three-dimensional design of auxetic materials.

An advanced tool for designing auxiliary materials

“This is a big step forward for assistive technologies,” said NIST Materials Research Engineer Edwin Chan, co-author of the study. “We can actually optimize the material to have any specific mechanical properties and behaviors that you want.”

The behavior of elastic materials is described in part by the Poisson’s ratio, which describes how the material changes shape when stretched or compressed in one direction. Most materials have a positive Poisson’s ratio, which means that compressing them in one direction makes them wider and/or thicker in other directions. Stretching them makes them narrower and/or thinner.

Excipients have a negative value of the Poisson ratio and act in the opposite way.

When you puncture a non-selective material, it thins and expands laterally. When you puncture a auxiliary, the material bunches up and narrows in width. Under the right conditions, this provides greater impact resistance. For example, if you hit a bag full of water (like on a hiking trip), the water inside will flow out on impact. If the bag were filled with auxiliary foam, the material would become even denser and stiffer on impact.

Potential applications in the field of safety and comfort

This is one reason why auxiliary materials are being considered for use in buildings and cars. They can provide greater protection against explosions and collisions. The auxiliary gel or rubber foam found in the insoles of running shoes provides better cushioning when the foot hits the ground.

In clothing, supportive nylons, fibers, and other synthetic materials can be more comfortable than traditional materials. Because they expand when stretched, they distribute pressure more effectively across the body, potentially reducing stress on the back, joints, neck, and shoulders. A study of the use of support materials in bra straps found that “Polyester and nylon support structures exhibit excellent pressure distribution capabilities.”

The design tool, developed by scientists at NIST and the University of Chicago, is an “inverse design” algorithm, meaning users can input the desired Poisson ratio value for the support materials. The algorithm then recommends an optimized material structure.

Another way to express the Poisson ratio is that it describes the relationship between shape and volume when shape and volume change. A new algorithm allows fine-tuning of this relationship to create support materials that behave in ways not found in nature.

“Our research is a great example of how theoretical, experimental, and computational sciences work together to realize something new,” said Marcos Reyes-Martinez, a materials research engineer at NIST. “Finding a way to make auxetics better will allow them to become more common in our daily lives.”

The researchers have patented the algorithm, the methodology behind it, and its implementation using 3D printing.

Source: Port Altele

As an experienced journalist and author, Mary has been reporting on the latest news and trends for over 5 years. With a passion for uncovering the stories behind the headlines, Mary has earned a reputation as a trusted voice in the world of journalism. Her writing style is insightful, engaging and thought-provoking, as she takes a deep dive into the most pressing issues of our time.