Chemists at the University of California at Santa Cruz have discovered a new way to produce biodiesel from waste oil, which simplifies the process and requires relatively moderate heating. This discovery could make an alternative fuel source much more attractive to the major industrial sectors that form the backbone of the country’s economy.

In 2022, the US transportation sector alone used nearly 3 million barrels of diesel per day; This accounts for approximately 75% of the total fuel consumption in this country. That same year, diesel fuel use accounted for about 10% of total CO2 emissions, according to the federal Energy Information Administration.2, It’s about energy in the USA.

While some companies are turning to electric vehicles to reduce their carbon footprint, the vast majority of fleets still run on diesel fuel; This is partly because biodiesel is complex and energy-intensive to produce, thus slowing adoption. In 2022, biofuels accounted for only 6% of all energy sources used by the US transportation sector.

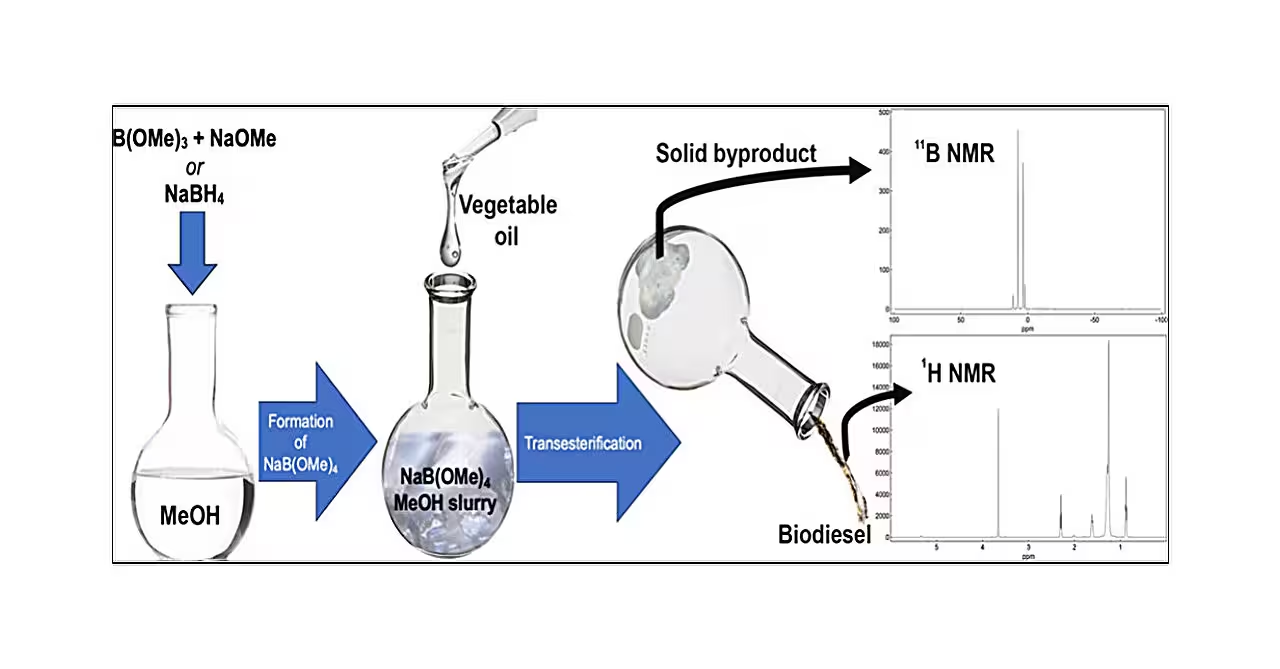

In their study published in the journal on October 3 Energy and FuelsLead author Kevin Lofgren describes a new method for converting used vegetable oil into biodiesel fuel containing sodium tetramethoxyborate (NaB(OMe)).4). This chemical, used to create the active ingredient that reacts with petroleum to produce biodiesel, is thought to be unique because it allows the biofuel to be easily separated from the byproducts of production by simple filtration.

Another advantage is that the resulting by-product can be used to regenerate the most expensive component in the production process. Finally, the reaction can be completed in less than an hour at temperatures up to 40°C (104°F), saving energy and money.

Lofgren, Ph.D. “I always wanted to work on biodiesel,” he said. student in the Department of Chemistry at the University of California, Santa Cruz. “I started researching this new material we were making to see if it would affect the fats in the oil to help catalyze biodiesel, and that’s where it all came from.”

Also read – New satellite technology tracks plastic on beaches and helps clean up remotely

While individual consumers are increasingly turning to solar and electric power to power their homes and vehicles, America’s vast industrial sectors still rely on diesel. Lofgren emphasized that the majority of trucks, trains and boats that transport goods around the world are currently powered by diesel engines and will not become electric anytime soon.

The researchers also point out that biodiesel is a carbon-neutral fuel available today and certified to power these vehicles without the need for engine modifications.

Reducing the energy required for biofuel production

Some of the current biodiesel production methods produce soap as a by-product, making it difficult to clean the fuel and resulting in less product production. Other approaches rely on oil palm, which requires cutting down trees in rainforests to make way for monoculture palm plantations. These methods are also energy intensive and require extremely high temperatures and pressures. The technology described in this study makes it possible to produce biodiesel at a lower temperature than the temperature required to boil water.

“It takes a lot of energy to produce energy,” said co-author Scott Oliver, professor of chemistry and biochemistry. “Our method uses waste oil and moderate heating, compared to existing refineries that consume energy and pollute the environment.”

According to the researchers, the method they discovered converts approximately 85% of used vegetable oil into biodiesel and meets nearly all industry standards for use as a fuel in heavy machinery and vehicles. The exception was water content, but it was only slightly above the permissible value. The researchers expect the water content to reach an acceptable level when this process is scaled up.

“This new method is special because it is simple and affordable. It has the advantage of being able to reproduce the source material,” Lofgren said. “It’s already cheap enough to compete. “But if you can buy the most expensive material once and then rebuild it, it will be more cost-effective in the long run.”

Also read – Scientists turned polystyrene waste into a clean energy source

“Everyone needs energy; every farm, food processing plant and vehicle depends on it,” Oliver said. “It can really affect people. This process can be performed slightly above room temperature and used repeatedly. You don’t need to own a refinery; You can potentially use this method on the farm.

Baktan Singaram, professor of chemistry and biochemistry at the University of California, Santa Cruz, is the corresponding author of the paper “Borate pathway from waste oil to FAMEs under near-environmental conditions.”

Subscribe to our Telegram channel