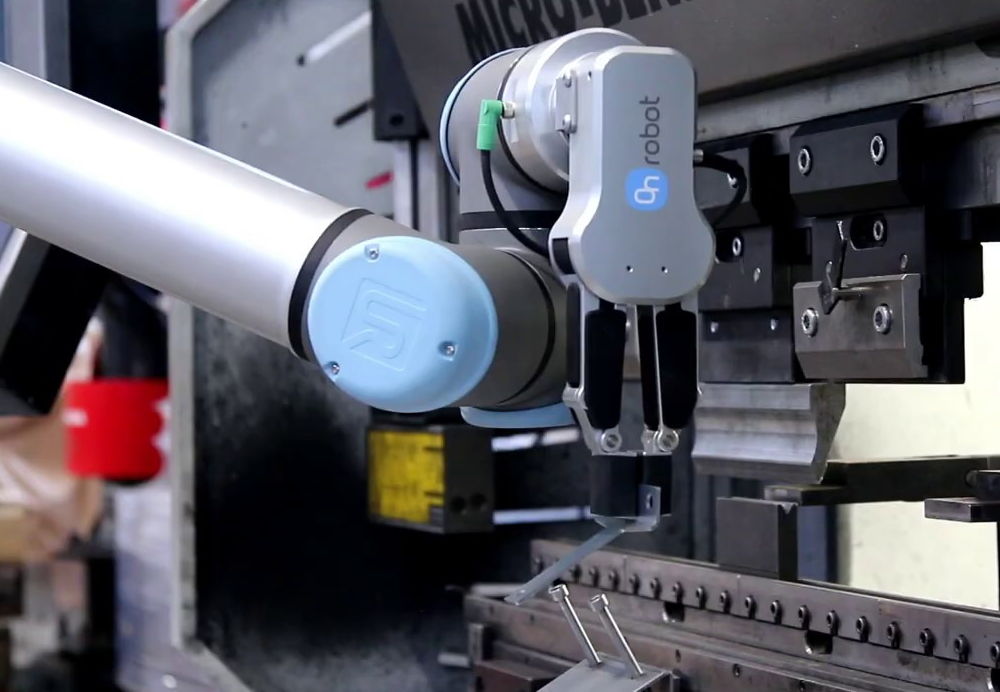

Collaborative robotics, known as Cobots, is a branch of robotics that is characterized by the way robots are combined with humans. Basically, it is a type of robot that can work hand in hand with your employees.

The use of these bots is growing as more and more companies are betting on them with different types of collaborative bots on the market. Next, we will tell you 5 ways Cobots help companies in automating processes.

1) They facilitate its implementation

One of the most striking features of collaborative bots is how easy they are to implement. Its very nature means that the learning and adaptation curve for employees is practically minimal, reducing the time it takes for companies to get used to the technology.

The requirements for technological, human, infrastructural and economic resources are much lower compared to other types of industrial robots. This not only helps to reduce the time and cost of implementation but also opens up the market for them. Now Cobots can be implemented by more companies from different sectors.

2) Its easier learning

Designed to work hand-in-hand with your employees, this class of bot stands out for its relative simplicity. Although these are complex machines in their technology, they are easier to understand because they require less training and specialization to handle them.

Companies investing in a robot for the first time will find a great option here. Indeed, companies that do not have robotics generally do not have specialized teams. A collaborative robot simplifies this area by reducing the need for specialization. Although the know-how behind Corobot needs to be trained, it is easier for companies to comply.

3) Their operation is safer

There are robots that for their work require the definition of work areas and also the introduction of specific safety measures. In the case of collaborative robots, this is not necessary.

To achieve this, these types of robots use high-tech sensors as well as artificial intelligence to define certain control parameters. The accident rate is lower and the safety instructions for operating robots are less demanding.

4) Much cheaper

If we compare the cost of a conventional industrial robotic machine with a collaborative robot, Corbots are much cheaper. And that for two reasons, primarily the technology behind the operation of the robot.

Second, since they do not require limited work areas and a more complete infrastructure, the costs of their implementation are lower. On the other hand, an increase in productivity brings with it a faster return on investment, lower operating costs and an increase in the company’s profit, these are points that also affect its price.

5) They can be implemented in different processes

Finally, another way Corobots help automate companies is their great versatility. Today, this class of robots can be implemented in various types of processes.

From administrative processes to industrial processes can be automated with a collaborative robot. This translates into the ability of companies to improve not only their productivity in the production area, but also efficiency in other departments. In addition, of course, they can be implemented in various industries such as automotive, food, pharmaceutical, technology and others.