The chip crisis will not ease until 2024 and prices will remain high

- April 13, 2022

- 0

Despite the fact that there are different voices that reassure himcrisis due to lack of chips will begin to recede in 2023, and some even suggest that improvements

Despite the fact that there are different voices that reassure himcrisis due to lack of chips will begin to recede in 2023, and some even suggest that improvements

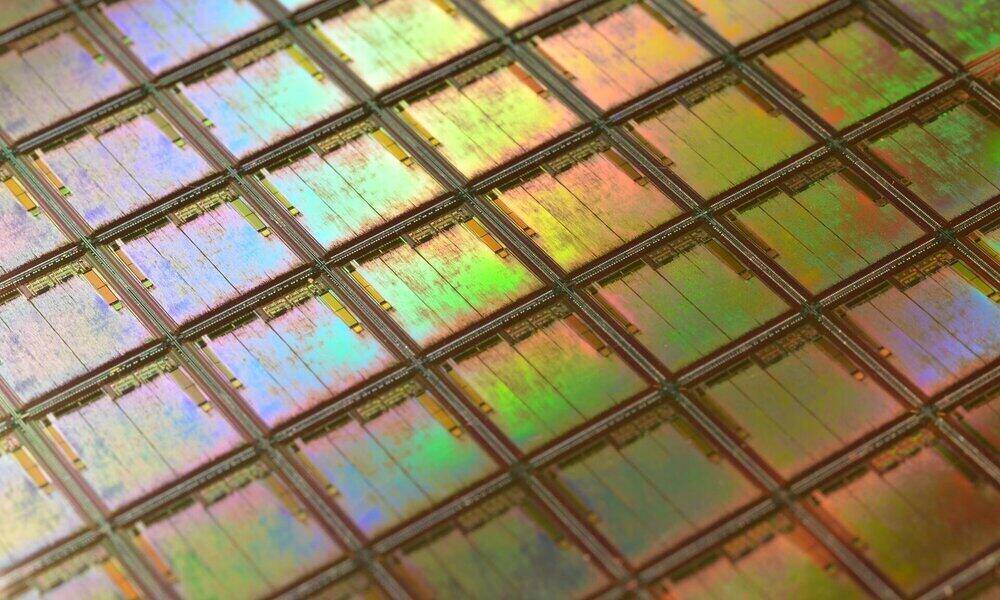

Despite the fact that there are different voices that reassure himcrisis due to lack of chips will begin to recede in 2023, and some even suggest that improvements will be seen earlier, as early as the end of 2022, new voices, including Volkswagen, point out that it will not be completed until 2024year in which it is Several wafer factories are expected to open and operatebasic component for the production of chips and components.

The consulting firm Techcet warned that the demand for silicon wafers by the end of 2023 would exceed the available supply, which would delay the production of some chips, which could also shoot up the prices of various components. Wafers are bases on which chips are placed for the production of components, so they cannot be assembled without them.

At present, according to the consultant, the production of 300 mm wafers will barely meet demand, and moreover, this demand will grow in the coming months. Many owners of the plants that produce them have decided to increase their production, but they will not be able to do so until they increase their production capacity, which will not be possible until 2024.

As the director of the consulting company The Register said, this will lead to «prices are rising due to the delicate balance between supply and demand and also because suppliers are demanding higher prices in contracts to pay for new investments. In addition, energy and raw material costs are rising in the short term, which is putting upward pressure on silicon wafer prices. Starting in 20202, there was a high demand for silicon wafers, and during this period, wafer suppliers invested very little in new plants to produce the wafers needed to assemble semiconductors. It is only in the last six months or so that they have announced plans to invest in new plants, although their production for the semiconductor sector will take about two years.«.

Techcet assumes that proceeds from the sale of silicon wafers, due to rising prices, will be $ 15,500 million, up 14.8% from 2021. On the other hand, SEMI, the main consortium in the sector, said manufacturers around the world are increasing their production capacity to 200 -millimeter plates to meet demand. Their production capacity will reach 6.9 million wafers per month by 2024, compared to 1.2 million wafers they could produce at the end of 2020.

All indications are that wafer manufacturers will add approximately 25 new 200 millimeter wafer production lines over the next five years, primarily to meet demand in areas such as 5G, the automotive industry or the Internet of Things. SEMI also points out that this increase in production will be used primarily for the production of low-cost chips, which include analog and energy management chips, as well as circuitry for screens.

Source: Muy Computer

Alice Smith is a seasoned journalist and writer for Div Bracket. She has a keen sense of what’s important and is always on top of the latest trends. Alice provides in-depth coverage of the most talked-about news stories, delivering insightful and thought-provoking articles that keep her readers informed and engaged.