Robotics have used a method reminiscent of the traditional art of paper folding to build autonomous machines from thin, flexible sheets. These lightweight robots are simpler and more cost-effective to manufacture, and their more compact form makes them easier to store and transport.

However, the usual requirement for stationary computer chips that provide advanced capabilities such as sensing, analysis, and adaptability adds additional weight to sensitive sheet materials and makes them difficult to assemble. As a result, semiconductor components must be added after the job is finished.

Now, an interdisciplinary team led by researchers at UCLA’s Samuel School of Engineering has created a new technique for making fully foldable robots that can perform a variety of complex tasks without relying on semiconductors. A study has been published that includes a detailed description of the results of the study. Nature Communication.

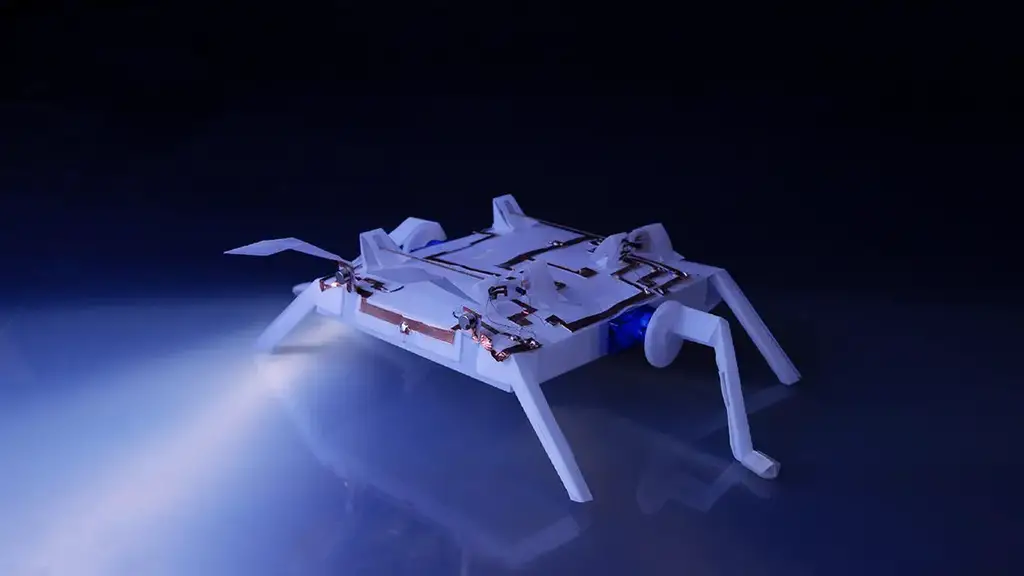

By adding flexible and conductive materials to the pre-cut thin polyester film, the researchers created a system of computing units, or transistors, that can integrate with sensors and actuators. They then programmed the page using simple computer analog functions that mimicked the functions of semiconductors. After being cut, folded and folded, the sheet becomes an autonomous robot that can accurately sense, analyze and react to its environment. The researchers named their robot “Origami Mechs,” an acronym for Origami MechanoBots.

“This work leads to a new class of origami robots with enhanced capabilities and levels of autonomy, while retaining the advantages of origami-based manufacturing,” said lead study author Wenzhong Yan, a mechanical engineering doctoral student at UCLA.

OrigaMechs derive their computational power from a combination of mechanically multiplexed origami keys created by folds and programmed with logic instructions such as VE, OR, and NOT. The switches activated a mechanism that selectively outputs electrical signals based on varying pressure and heat input into the system.

Using a new approach, the team created three robots to demonstrate the system’s potential:

- Insect-like walking robot that changes direction when one of its antennas detects an obstacle

- a flytrap-like Venus robot that envelops “prey” when both sensors in its jaws detect an object

- a reprogrammed two-wheeled robot that can move along predesigned trajectories with different geometric patterns

While the robots are connected to a power source for the demonstration, the researchers said the long-term goal will be to equip autonomous origami robots with an integrated energy storage system powered by thin-film lithium batteries.

The chipless design could allow robots to operate in extreme environments (places with strong radiation or magnetic fields and intense radio frequency signals or strong electrostatic discharges) where conventional semiconductor-based electronics might not work.

“Such dangerous or unpredictable scenarios, such as during natural or man-made disasters, can be particularly beneficial for origami robots,” said lead researcher Ankur Mehta, professor of electrical and computer engineering and laboratory director at UCLA. . for embedded machines and ubiquitous robots.

“Robots can be designed for specific functions and produced on demand very quickly,” Mehta said. “Also, while very distant, there may be environments on other planets where robot explorers immune to such scenarios would be highly desirable.”

Pre-assembled robots created using this flexible “cut and assemble” technique can be transported in flat packs to save a lot of space. This is important in scenarios like space missions where every cubic centimeter counts. Inexpensive, lightweight and easy to manufacture robots could also lead to innovative teaching tools or new types of toys and games.