The fact that the carbon footprint of the car industry is quite high means that the giant companies in this field are looking for a more sustainable future. to electric cars provides orientation. Many major brands from around the world introduce their new electric cars every year and say they will abandon traditional vehicles by the 2030s.

However, batteries are used for the production of such electric vehicles. neodymium Elements with high costs and effects are needed. Here, a 17-year-old teenager in the US says he has designed an engine that can be used to produce electric cars that don’t require these rare elements.

Why do we need to get rid of rare elements?

First, let’s talk a bit about the effects of these rare earth elements. Elements such as neodymium, which produce the magnet used in vehicle engines, currently play a key role in the components that power electric vehicles. If we open more, electric vehicles will be made of such elements to get power. of magnets uses. However, these elements also have some drawbacks.

Heath Hoffman, a professor at the University of Michigan who is heavily involved in electric vehicles, said that the demand for rare elements such as neodymium, samarium and dysprosium is very high, and that magnetic motors are very is not sustainable sends. He also emphasizes that there is a demand for these elements from various disciplines.

According to experts, the extraction of such rare earth elements both financially and ecologically can lead to bad consequences. The extraction of such elements harms the environment and undermines the sustainability of electric vehicles. In addition, the cost of the elements is quite high. Weight of a rare element for comparison hundreds of dollars can be sold; however, the weight of a common element such as copper turns out to be 7-8 dollars. This shows the huge difference in costs.

17-year-old Sansone wants to end the need for rare elements in electric cars

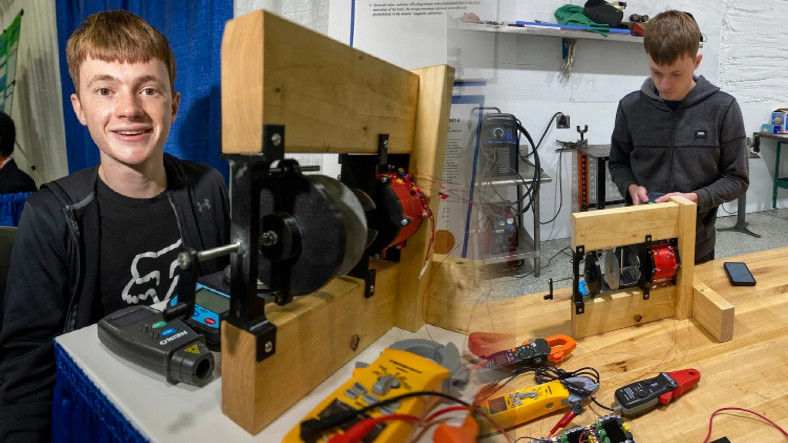

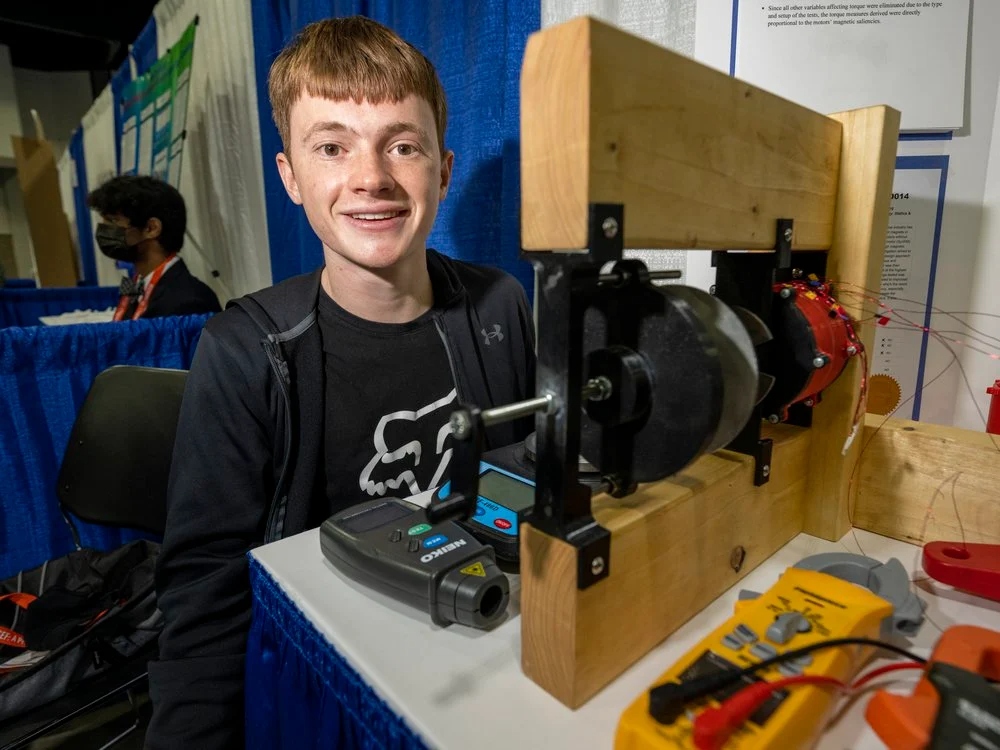

17 years old Robert Sansoneis a young man who has been involved in technology for a long time. This friend of ours in Florida, USA, has done 60 different engineering projects so far. But the last thing he’s done is a project that has the potential to make a huge contribution to the future of humanity.

Sansone says he came across a video about the pros and cons of electric vehicles two years ago, in which he recognized the need for rare elements. The young man stated that he was interested in electric motors and then decided to design another motor that could contribute to sustainability.

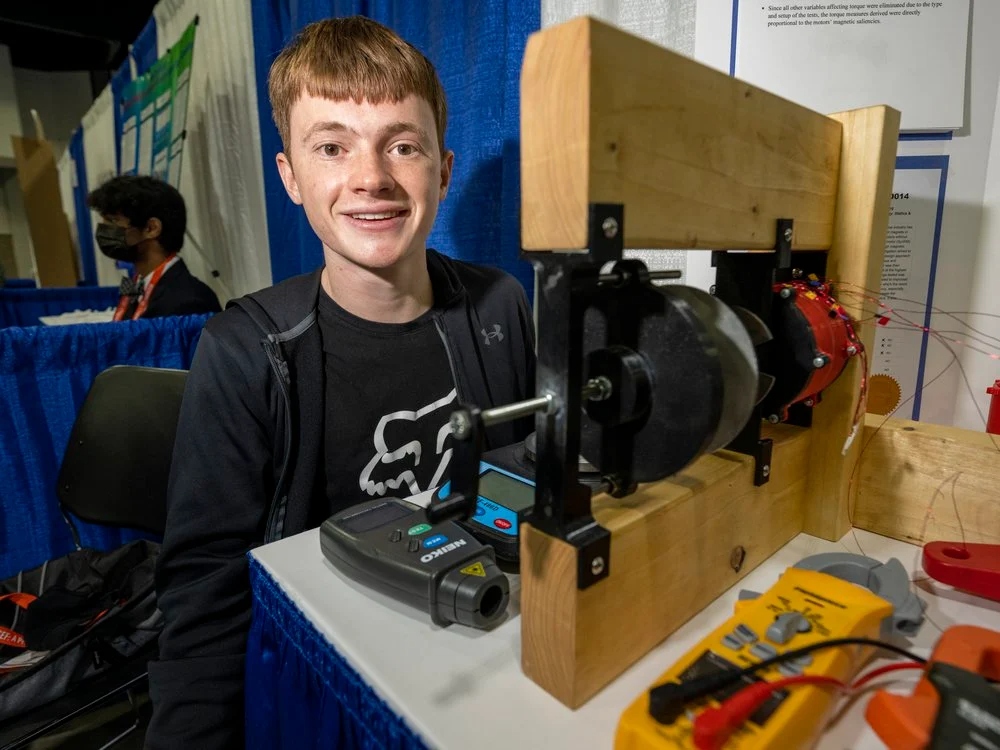

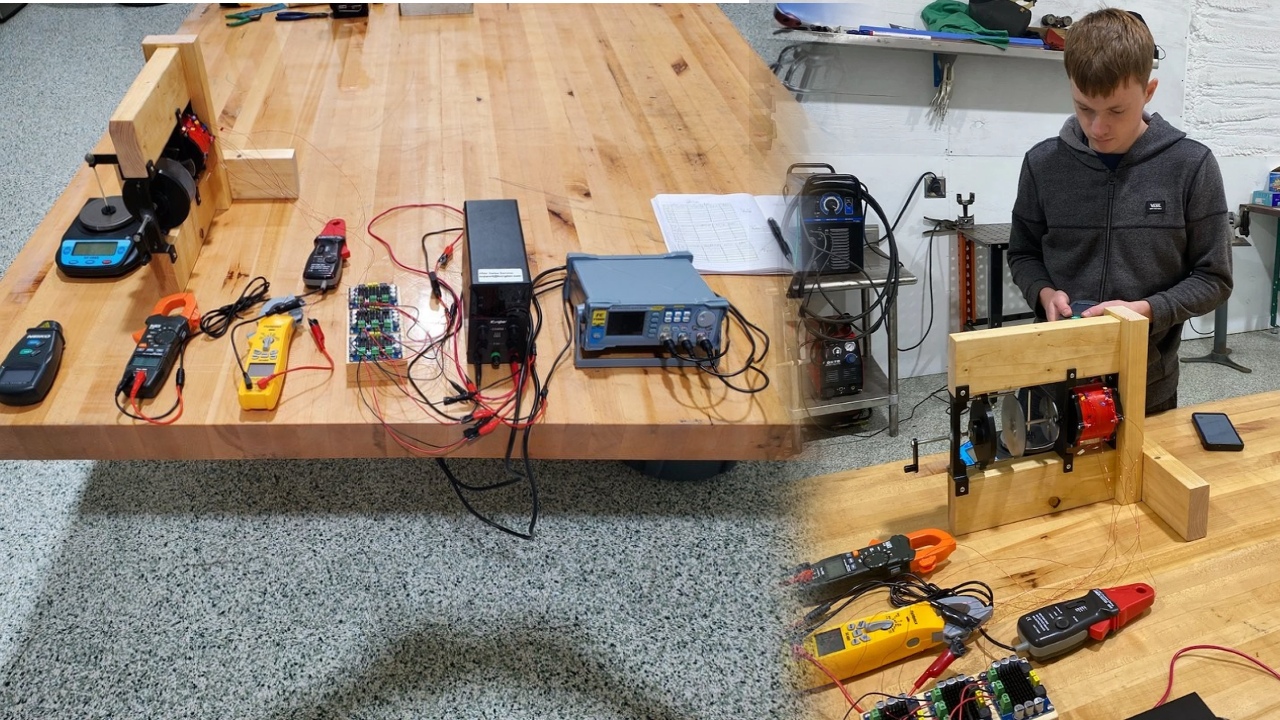

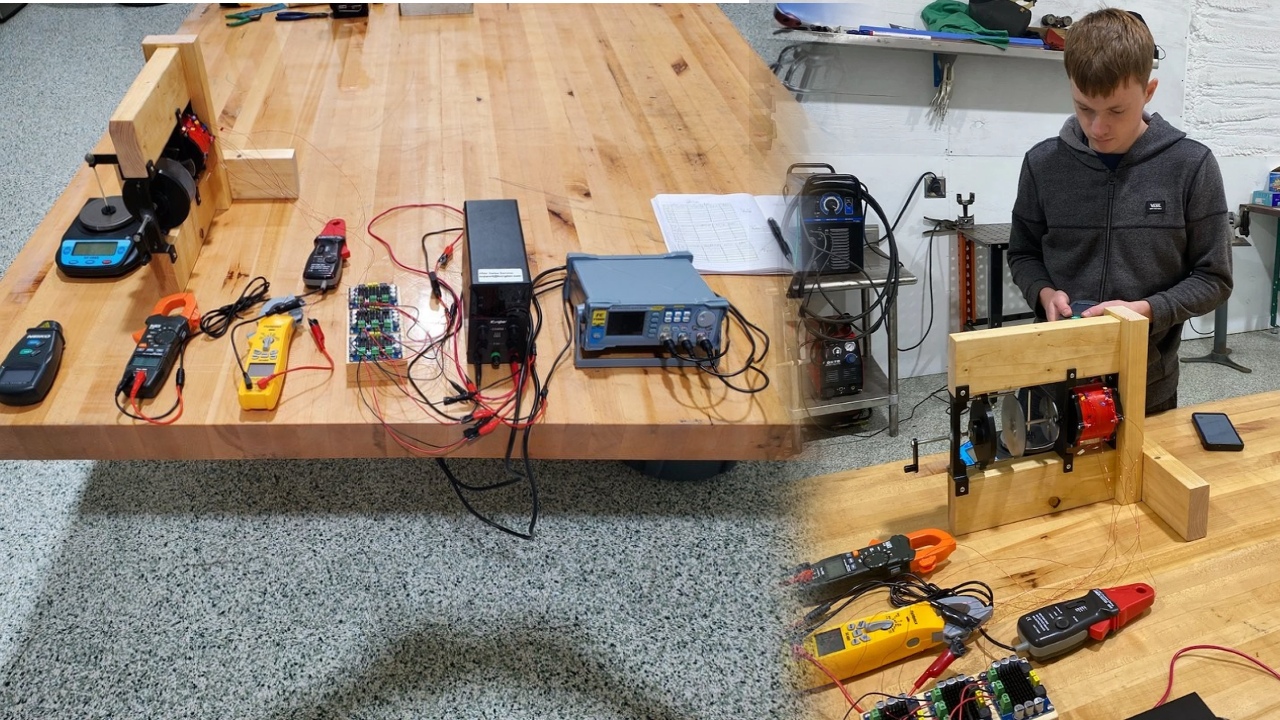

Reluctance motors electric motors, named after him, do not require rare earth elements. These motors, which are not powerful enough to be used in electric vehicles, are currently used in tools such as pumps and fans. Sansone stated that he had heard of these motors before and started trying to improve the performance of the reluctance motor. High school student runs for a year, off existing motorbikes more torque and efficiency made a prototype.

According to the descriptions, this prototype was made of plastic, copper wires and a steel rotor made by 3D printing. These works by Sansone were presented to him at the Regeneron International Science and Engineering Fair in the US. first place and $75,000 prize earned.

“Being fully sustainable with my bike means that my dreams come true”

Reluctance motors use steel rotors and air gaps. Sansone states that he thinks that instead of using the air gap to increase the reluctance (magnetic resistance) ratio, he can add another magnetic field to the motor. After 15 failed attempts The young engineer adds that he has managed to produce a working prototype and avoids giving more details about the project as he plans to obtain a patent for his technology in the future.

Finally, it was mentioned that Sansone tested the prototype for efficiency and torque. As a result of these tests, the design was completed at 300 cycles. 39% more torque and 31% more efficiency was seen to exhibit. Heath Hoffman of the University of Michigan said Sansone’s project showed promise; but the production of such restraint engines complex and difficult He points out that this is the biggest limiting factor for the idea. Sansone, on the other hand, agrees with Hoffman; however with new technologies such as 3D printing He says that this problem can be solved in the future.

“It would be a dream come true to see electric cars produced using my new engine design that are sustainable from the ground up.” Based on his statements, Sansone states that he is currently working on the 16th version of his bike. If the motor continues to run at high speed and efficiency, the young engineer obtaining a patent Finally, he adds that he will go through the process. We will see in the coming years whether such engines, which have the potential to make electric cars fully sustainable, are used.