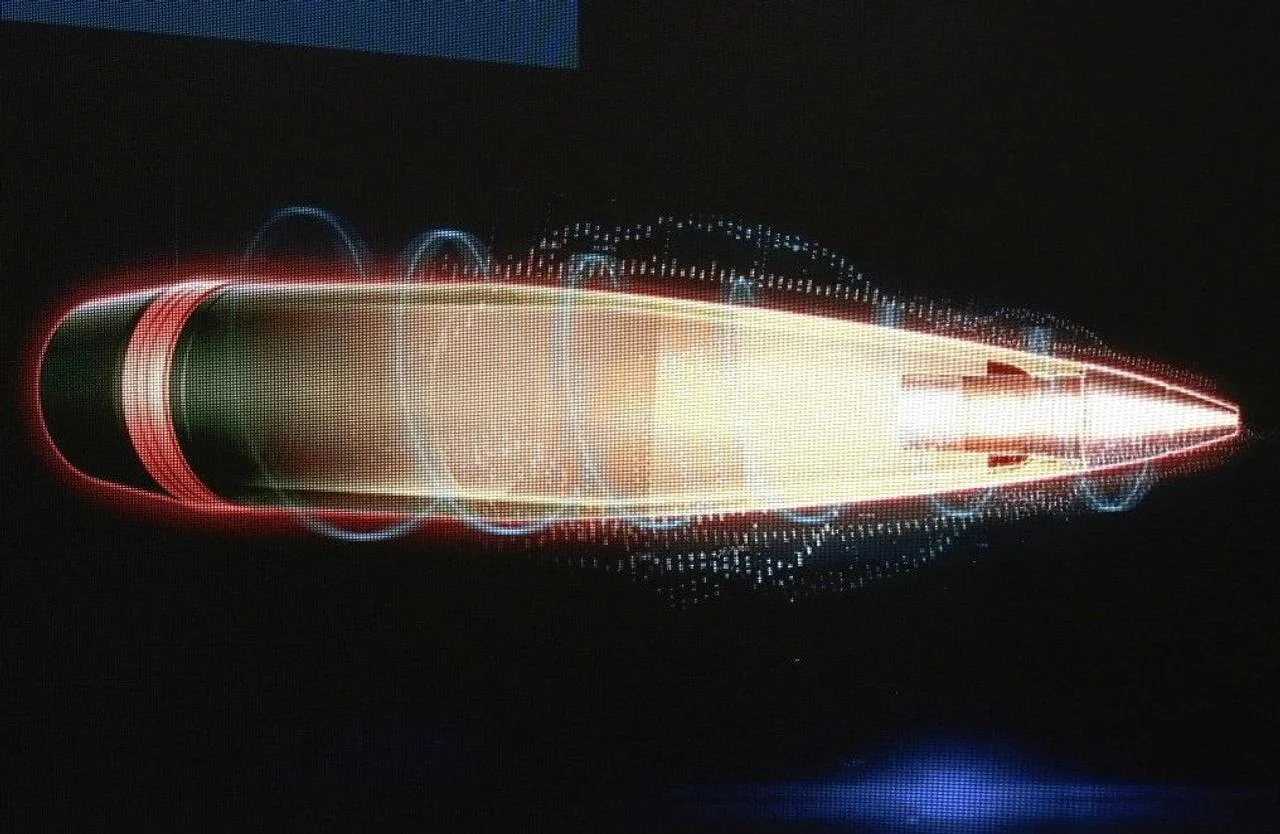

Defense concern BAE Systems has presented a new technology that will simplify and speed up the production process for the production of artillery ammunition. The new generation of NGAA artillery ammunition should solve the fundamental problem of cost and mass production.

Current production problems need to be solved with an integrated approach focusing on the use of less specialized materials currently used in civilian industry and unrelated to the field of defense.

This will allow pre-existing civilian businesses to be used to mass produce munitions when needed, as well as integrate defense production into the civilian supply chain.

“We will manufacture the ammunition casing from industrial grade steel, moving away from the specialized raw materials used so far. This will allow us to purchase it from a much larger number of suppliers,” explained BAE Systems representatives.

In order to be as close as possible to the properties of the steel used in ammunition production, BAE Systems engineers apply heat treatment.

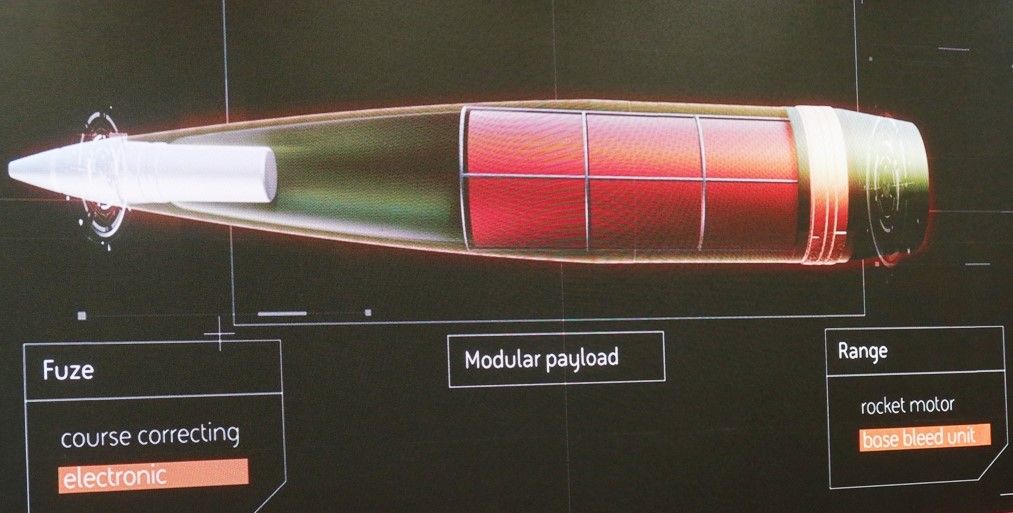

In addition, the NGAA family of ammunition is designed to have a solid body, which will greatly facilitate the production of existing samples, the body of which consists of several parts.

The new manufacturing technology received an innovation as part of the process of filling the casing with explosive material. Instead of classical injection molding of plasticized explosives into the body, the engineers involved want to use “resonant acoustic mixing” technology. The new method will reduce the process from hours to minutes while reducing costs and waste.

NGAA ammunition will receive a completely electronic fuze-missile e-Fuze, which is revolutionary in its field, replacing old mechanical analogues.

Competitiveness is an important issue and that is why BAE Systems aims to use new technology to reduce the cost of producing a single ammunition by up to 75%. Source

Also read – Xiaomi leaves the competition behind thanks to voice recognition technology