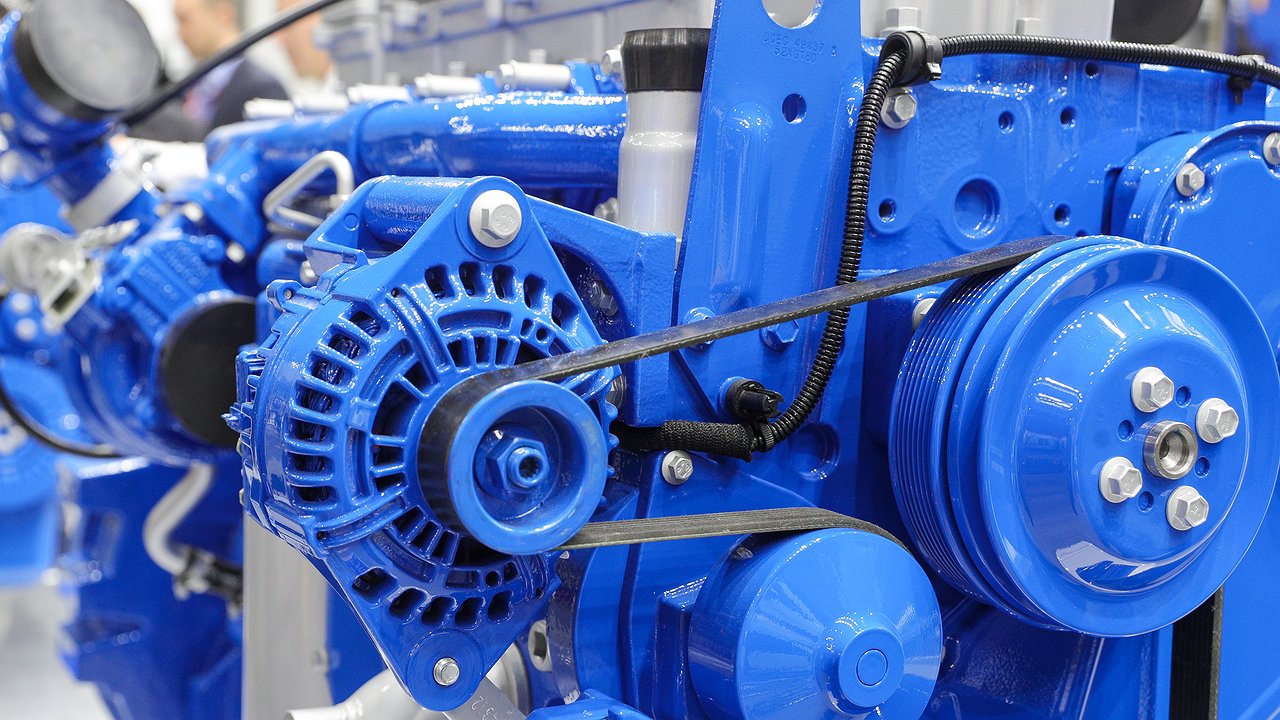

Employees of the Agricultural Academy of the RGAU-MSHA named after KA Timiryazev have developed a new type of internal combustion engine. The invention promises to be cheaper and more durable than existing engines.

Almost fantastic news comes from the scientific depths of the Timiryazev Agricultural Academy in Moscow. It turns out that they not only invent new ways of planting potatoes, but also hone the forefront of scientific and technological progress in mechanical engineering: a team of scientists from Timiryazevka patented the design of a new type of internal combustion engine.

Materials are used that make the use of lubricants and maintenance of combustion engines superfluous. The friction between the piston and the cylinder in this engine tends to zero, which allows us to talk about an increase in the resource of the whole mechanism by about a factor of two compared to power units built according to the schemes of a classic internal combustion engine and a 3-5% increase in efficiency. Another advantage of the development is that the weight and dimensions are about a third lower than conventional internal combustion engines.

Also, costs are 30% lower – this is achieved by ceasing foundry production activities in favor of stamping. The engine of the patented academy design is designed to run on gasoline or gas fuel. But there is no data on its efficiency.

Now the creators of the novelty are trying to find a partner to organize the mass production of their offspring, reports RIA Novosti.

Almost fantastic news comes from the scientific depths of the Timiryazev Agricultural Academy in Moscow. It turns out that they not only invent new ways of planting potatoes, but also hone the forefront of scientific and technological progress in mechanical engineering: a team of scientists from Timiryazevka patented the design of a new type of internal combustion engine.

Materials are used that make the use of lubricants and maintenance of combustion engines superfluous. The friction between the piston and the cylinder in this engine tends to zero, which allows us to talk about an increase in the resource of the whole mechanism by about a factor of two compared to power units built according to the schemes of a classic internal combustion engine and a 3-5% increase in efficiency. Another advantage of the development is that the weight and dimensions are about a third lower than conventional internal combustion engines.

Also, costs are 30% lower – this is achieved by ceasing foundry production activities in favor of stamping. The engine of the patented academy design is designed to run on gasoline or gas fuel. But there is no data on its efficiency.

Now the creators of the novelty are trying to find a partner to organize the mass production of their offspring, reports RIA Novosti.

Source: Avto Vzglyad

Donald Salinas is an experienced automobile journalist and writer for Div Bracket. He brings his readers the latest news and developments from the world of automobiles, offering a unique and knowledgeable perspective on the latest trends and innovations in the automotive industry.