Five tricks to kill a robotized DSG box

- June 27, 2023

- 0

Sometimes when you look at some “racers” you wonder how much you hate technology to drive like that. Jigitovka between lanes, cutting, playing “checkers” is not only dangerous

Sometimes when you look at some “racers” you wonder how much you hate technology to drive like that. Jigitovka between lanes, cutting, playing “checkers” is not only dangerous

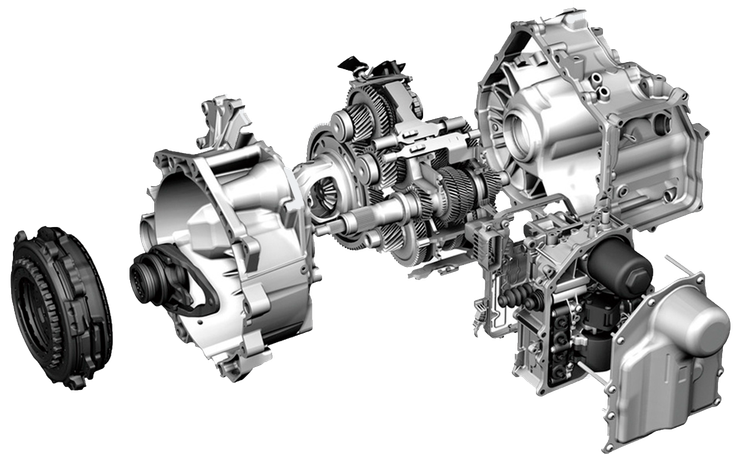

Cars with DSG drive damn well, for which many shortcomings are forgiven. Admittedly, unlike Porsche’s track robots, civilian versions of the DSG don’t have enough power to fly on the road like on the track. This means that killing the German “robot” DSG with sporty driving is as easy as shooting pears. DSG7 DQ200 and DSG6 DQ250 boxes cannot withstand strong impact loads. Therefore, the surest way to kill the box is chip tuning, which reconfigures the engine and changes the operation of the clutch unit.

It is considered the highest chic to install lunch control on your “swallow”, as on a Porsche 911. Indeed, a two-clutch “robot” after software intervention allows you to start spectacularly. You press the gas and brake at the same time, turn the tachometer needle to the red zone and then drop the pedal. The car brakes forward, leaving any slow movers behind.

It looks great, but you can’t envy the grip at such times. Chip tuning not only greatly increases the moment, but also shock loads break bearings, a fork, a hydraulic plate. As a result, something is “ringing” under the hood and the car has to be loaded onto a tow truck. The above method is universal for guaranteed destruction of many DSG parts. But there are also less spectacular tricks.

The problem areas of the “dry” DSG7 are the clutch block, shift fork and mechatronic parts. At the same time, even a “slow drive” can quickly burn the clutch. To do this, during a stop in traffic jams, you do not need to press the brake pedal to the end, but let the car move forward a little, as happens in cars with hydromechanical “automatics”.

The box goes into start mode, closes the clutch plates and makes them slip, that is, slip. The clutch rubs, overheats, the basket clogs with wear products and the mechatronics get hot. The longer the clutch slips, the lower the resource.

In addition, the clutch can overheat on long trips at speeds below 15 km / h in mode D. The algorithm for the operation of the “robot” assumes an instantaneous transition to second gear after starting and to get a To ensure smooth operation and get rid of shocks, the control unit releases the discs and lets them slide. The slower and smoother the car goes in stage two, the more the clutch slips. In general, if you want to destroy an expensive transmission, you should forget about the manual mode of the box, in which the driver himself selects the gear. To extend the life of the node, it is better to use the first stage in M mode at speeds up to 15 km / h, but this is so inconvenient …

Mechatronics – a technical unit for controlling the box. He himself squeezes the forks and shifts. And the node works under the control of the electronic unit, which is located in the case. The board is afraid of high temperatures, so the longer the clutch slips, the more likely the box will overheat and burn the chips. Usually this happens in the heat when performing the above methods of slipping. DSG mechatronics are erratic. At high engine speeds and heavy loads, the alloy hydraulic plate inside can break.

Most often this happens due to pressure surges when maintaining high speeds for a long time at high speeds, and manufacturing defects cannot be ruled out here. A crack appears, the oil pressure drops, the clutch slips and overheats. In general, the higher the engine speed, the less alive the mechatronic plate. You can find out the damage by oil stains on the gasket from the front of the box.

One of the weak points of a “dry” or “wet” DSG is the even-numbered fork. You can break it with a banal build-up of the car in the mud or in the snow. Remember how they left the snowy gruel in the winter in cars with “mechanics”? It is necessary to engage first and reverse gears alternately, giving the car forward and reverse impulses. The larger the structure, the stronger the car jumps back and forth in a snowdrift. If you catch the resonance, the car will come out automatically. However, such an algorithm is contraindicated for a “robot”, as it leads to an increased load on the fork and its plastic guides.

To facilitate transmission, DSG uses plastic parts that crack under excessive stress, leading to fork warping and locking. As a result, the reverse gear and associated even-numbered shift mechanism stop engaging. The fork is guaranteed to break if the reverse gear is stuck when the wheels slip, if they still rotate forward due to inertia, causing the reverse gear to engage with a jerk and sometimes even a creak. Then the transmission error message lights up on the dashboard.

If the even fork breaks, the machine can move very well on its own. You must reset the error and put the DSG in manual mode. Then you can forcibly pick out 1-3-5-7 gears and there is a chance to go to the gas station on your own. The car jerks but drives.

Cars with DSG drive damn well, for which many shortcomings are forgiven. Admittedly, unlike Porsche’s track robots, civilian versions of the DSG don’t have enough power to fly on the road like on the track. This means that killing the German “robot” DSG with sporty driving is as easy as shooting pears. DSG7 DQ200 and DSG6 DQ250 boxes cannot withstand strong impact loads. Therefore, the surest way to kill the box is chip tuning, which reconfigures the engine and changes the operation of the clutch unit.

It is considered the highest chic to install lunch control on your “swallow”, as on a Porsche 911. Indeed, a two-clutch “robot” after software intervention allows you to start spectacularly. You press the gas and brake at the same time, turn the tachometer needle to the red zone and then drop the pedal. The car brakes forward, leaving any slow movers behind.

It looks great, but you can’t envy the grip at such times. Chip tuning not only greatly increases the moment, but also shock loads break bearings, a fork, a hydraulic plate. As a result, something is “ringing” under the hood and the car has to be loaded onto a tow truck. The above method is universal for guaranteed destruction of many DSG parts. But there are also less spectacular tricks.

The problem areas of the “dry” DSG7 are the clutch block, shift fork and mechatronic parts. At the same time, even a “slow drive” can quickly burn the clutch. To do this, during a stop in traffic jams, you do not need to press the brake pedal to the end, but let the car move forward a little, as happens in cars with hydromechanical “automatics”.

The box goes into start mode, closes the clutch plates and makes them slip, that is, slip. The clutch rubs, overheats, the basket clogs with wear products and the mechatronics get hot. The longer the clutch slips, the lower the resource.

In addition, the clutch can overheat on long trips at speeds below 15 km / h in mode D. The algorithm for the operation of the “robot” assumes an instantaneous transition to second gear after starting and to get a To ensure smooth operation and get rid of shocks, the control unit releases the discs and lets them slide. The slower and smoother the car goes in stage two, the more the clutch slips. In general, if you want to destroy an expensive transmission, you should forget about the manual mode of the box, in which the driver himself selects the gear. To extend the life of the node, it is better to use the first stage in M mode at speeds up to 15 km / h, but this is so inconvenient …

Mechatronics – a technical unit for controlling the box. He himself squeezes the forks and shifts. And the node works under the control of the electronic unit, which is located in the case. The board is afraid of high temperatures, so the longer the clutch slips, the more likely the box will overheat and burn the chips. Usually this happens in the heat when performing the above methods of slipping. DSG mechatronics are erratic. At high engine speeds and heavy loads, the alloy hydraulic plate inside can break.

Usually this happens due to pressure surges when maintaining high speeds for a long time at high speeds, and manufacturing defects cannot be ruled out here. A crack appears, the oil pressure drops, the clutch slips and overheats. In general, the higher the engine speed, the less alive the mechatronic plate. You can find out the damage by oil stains on the gasket from the front of the box.

One of the weak points of a “dry” or “wet” DSG is the even-numbered fork. You can break it with a banal build-up of the car in the mud or in the snow. Remember how they left the snowy gruel in the winter in cars with “mechanics”? It is necessary to engage first and reverse gears alternately, giving the car forward and reverse impulses. The larger the structure, the stronger the car jumps back and forth in a snowdrift. If you catch the resonance, the car will come out automatically. However, such an algorithm is contraindicated for a “robot”, as it leads to an increased load on the fork and its plastic guides.

To facilitate transmission, DSG uses plastic parts that crack under excessive stress, leading to fork warping and locking. As a result, the reverse gear and associated even-numbered shift mechanism stop engaging. The fork is guaranteed to break if the reverse gear is stuck when the wheels slip, if they still rotate forward due to inertia, causing the reverse gear to engage with a jerk and sometimes even a creak. Then the transmission error message lights up on the dashboard.

If the even fork breaks, the machine can move very well on its own. You must reset the error and put the DSG in manual mode. Then you can forcibly pick out 1-3-5-7 gears and there is a chance to go to the gas station on your own. The car jerks but drives.

Source: Avto Vzglyad

Donald Salinas is an experienced automobile journalist and writer for Div Bracket. He brings his readers the latest news and developments from the world of automobiles, offering a unique and knowledgeable perspective on the latest trends and innovations in the automotive industry.