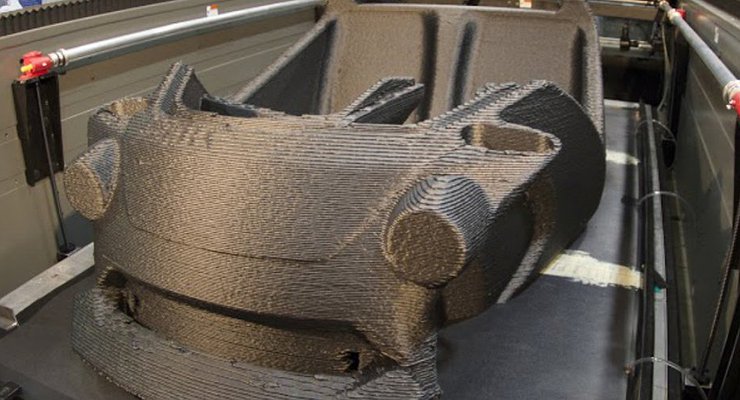

The main thing here is a modern metal printing 3D printer. Allows you to choose an individual configuration for printing with a specific metal powder. And this powder is melted by a laser.

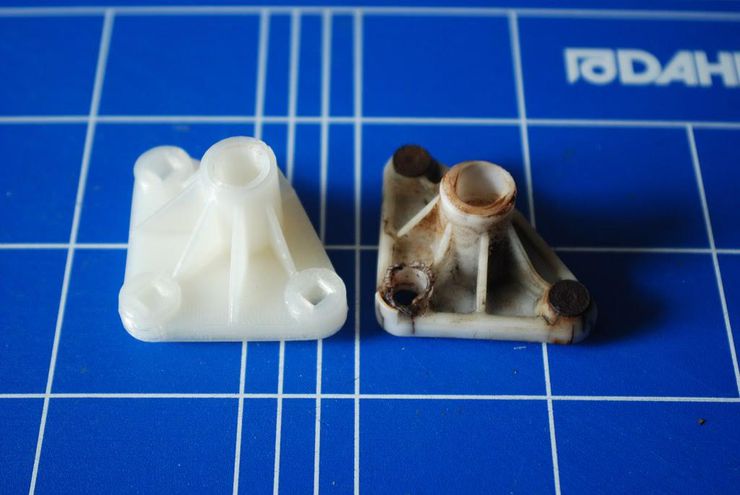

However, it should be remembered that the rigidity of the printed part is lower than that of the molded part. Therefore, we do not recommend the use of such spare parts, for example in an engine or suspension. For example, it is not possible to print the entire crankshaft. This is a very big detail, which means it has to be done in parts. And the connection of these parts will lead to errors, and it will be difficult to balance such a crankshaft. If you take the chance and install it in the engine, no one can guarantee how long the spare part will last and how the engine will run. High temperatures will most likely just cause it to fall apart and the power supply will die.

Replacing the timing mechanism rollers with printed copies may also destroy them. Then the revision is guaranteed. As for the chassis, here too it will not be possible to make a large wishbone from one piece of metal. And if you cut it into pieces, it just won’t withstand the blow and will split.

That is, we repeat that 3D printing is suitable for the manufacture of fastening elements, for example, a bumper, or decorative interior elements. Therefore, do not blindly rely on new technologies. First estimate the repair costs. It may be more economical to order parts and wait three or four weeks, rather than paying hefty money to manufacture them through 3D printing.

SUBSCRIBE FOR EXCLUSIVE CONTENT

PORTAL “AVTOVGLYAD” IN TELEGRAM