Why is electric power steering more dangerous than power steering on a used car?

- October 17, 2023

- 0

When choosing a model of a used car, people, as a rule, think about the type of power steering installed on it, but this is the last thing

When choosing a model of a used car, people, as a rule, think about the type of power steering installed on it, but this is the last thing

Car manufacturers have been increasingly using electric power steering (EPS) instead of power steering for some time now. These units have less weight and are simpler in design. All advantages. Exactly until the moment the amplifier fails. This almost always happens after the original warranty on the car has expired. Therefore, the owner and employees of specialized gas stations are faced with emerging problems.

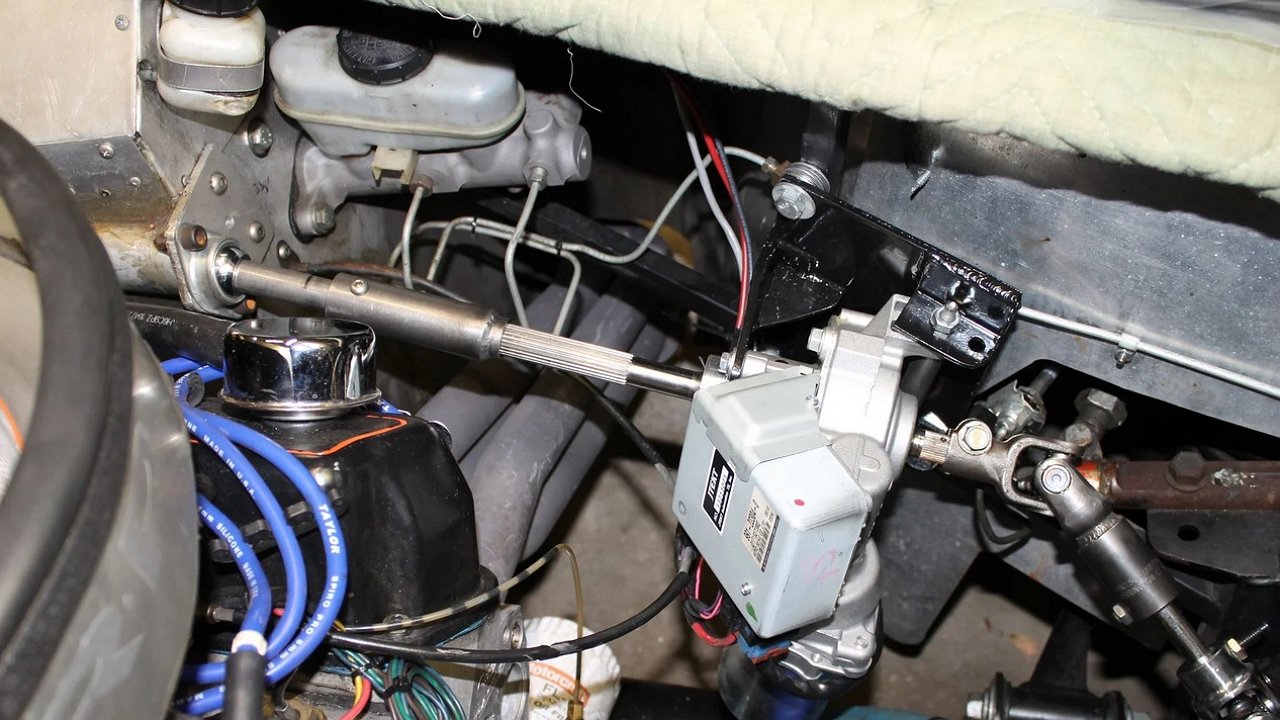

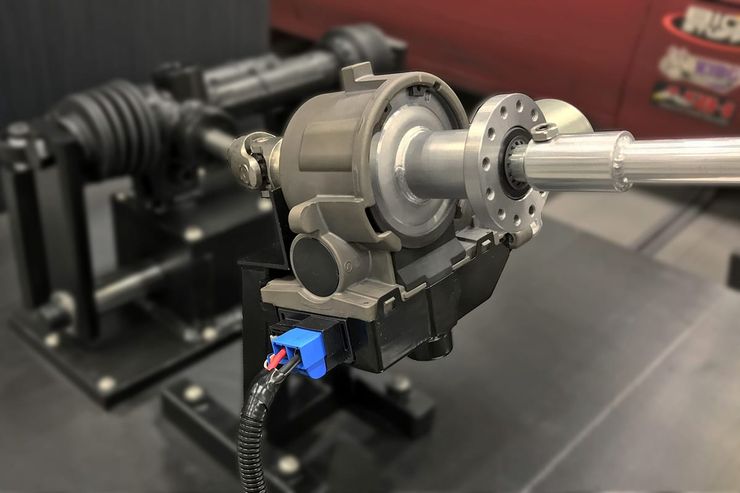

In short, virtually every part of the hydraulic booster can be repaired – both hydraulic and mechanical. That makes the event to bring the interchange back to life relatively cheap in terms of financial costs. With an electric booster, everything is much more complicated. Simply put, it consists of an electric motor, a control unit, a steering rack and various sensors. The hydraulic booster consists of a motor-driven pump, a hose valve system and a hydraulic power cylinder on a rack and pinion.

Leaking seals cause dirt and moisture to accumulate on the rod of any type of amplifier rack. They cause increased wear and corrosion of the teeth and threads. “Knocking on the wheel” comes from that. The power steering rack can be ground, adjusted and brought back to life. In principle, repairs are not provided for an electric amplifier, you will have to buy a new part. That is not budgetary at all.

There is also such a thing as a control unit for electric power steering. It is often installed on the rail itself. And usually they do not protect in any way against objects flying from under the wheels. When a pebble flies into its plastic casing, that’s it: moisture, corrosion and a complete ‘hello’ to the electronics. The treatment in the vast majority of cases consists in purchasing not only a new block, but also slats: they are “assembled”.

A common case of EUR failure is the ingress of moisture into the bearing of the electric motor, with subsequent corrosion. She announces herself with the howl of this structural element. This shame can be “repaired” in two ways: by installing a new electric motor with control unit, or by replacing the entire rack structure with a new one. Through a single bearing!

The electric booster has another treacherous part: a torque sensor. By itself it doesn’t often fail. In this case, it is simply replaced with a new one – if this is structurally possible on a specific model of electric amplifier. If not, replace the rack assembly again…

We can continue the list of ESD failures that can only be eliminated by an expensive “rack assembly replacement.” Against this background, the hydraulic booster is much more repairable, and therefore in a used car it is less dangerous for the car owner’s wallet.

Car manufacturers have been increasingly using electric power steering (EPS) instead of power steering for some time now. These units have less weight and are simpler in design. All advantages. Exactly until the moment the amplifier fails. This almost always happens after the original warranty on the car has expired. Therefore, the owner and employees of specialized gas stations are faced with emerging problems.

In short, virtually every part of the hydraulic booster can be repaired – both hydraulic and mechanical. That makes the event to bring the interchange back to life relatively cheap in terms of financial costs. With an electric booster, everything is much more complicated. Simply put, it consists of an electric motor, a control unit, a steering rack and various sensors. The hydraulic booster consists of a motor-driven pump, a hose valve system and a hydraulic power cylinder on a rack and pinion.

Leaking seals cause dirt and moisture to accumulate on the rod of any type of amplifier rack. They cause increased wear and corrosion of the teeth and threads. “Knocking on the wheel” comes from that. The power steering rack can be ground, adjusted and brought back to life. In principle, repairs are not provided for an electric amplifier, you will have to buy a new part. That is not budgetary at all.

There is also such a thing as a control unit for electric power steering. It is often installed on the rail itself. And usually they do not protect in any way against objects flying from under the wheels. When a pebble flies into its plastic casing, that’s it: moisture, corrosion and a complete ‘hello’ to the electronics. The treatment in the vast majority of cases consists in purchasing not only a new block, but also slats: they are “assembled”.

A common case of EUR failure is the ingress of moisture into the bearing of the electric motor, with subsequent corrosion. She announces herself with the howl of this structural element. This shame can be “repaired” in two ways: by installing a new electric motor with control unit, or by replacing the entire rack structure with a new one. Through a single bearing!

The electric booster has another treacherous part: a torque sensor. By itself it doesn’t often fail. In this case, it is simply replaced with a new one – if this is structurally possible on a specific model of electric amplifier. If not, replace the rack assembly again…

We can continue the list of ESD failures that can only be eliminated by an expensive “rack assembly replacement.” Against this background, the hydraulic booster is much more repairable, and therefore in a used car it is less dangerous for the car owner’s wallet.

Source: Avto Vzglyad

Donald Salinas is an experienced automobile journalist and writer for Div Bracket. He brings his readers the latest news and developments from the world of automobiles, offering a unique and knowledgeable perspective on the latest trends and innovations in the automotive industry.