The technology for the recovery of worn metal-intensive parts was proposed by scientists from three universities: NUST MISIS, Vavilov State Agrarian University and Kazan National Research Technological University.

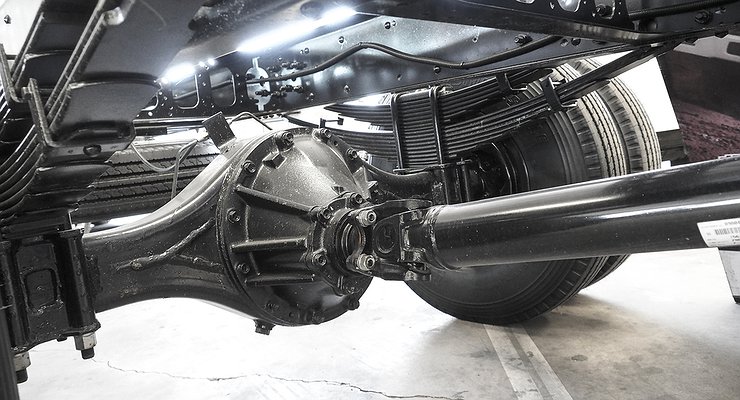

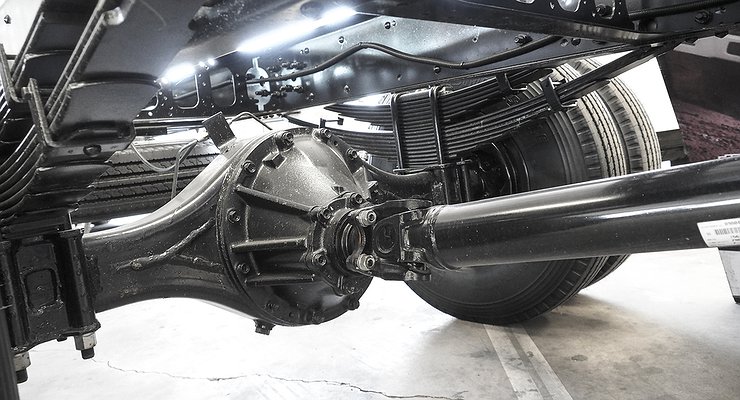

This process includes cleaning the worn part, welding the compensating layer, heating the workpiece, stamping, annealing the forging, machining and heat treatment. As a result, the part that survived the renovation is not inferior to the factory part in terms of properties.

For example, the cost of repairing one axle for a KamAZ truck is about 7,400 rubles, with an average price of a new one of more than 9,000. True, to master the technology, you need to buy equipment for as much as 900,000 rubles …

Meanwhile, even with Chinese spare parts, we may have trouble soon. The US Treasury Department continues to impose blocking sanctions. In addition, the new restrictions will be so strict that it will simply be impossible to obtain auto parts.