Relatively recently, another way to protect cars from corrosion has become widespread – zinc treatment. Let’s immediately make a reservation that in this case we are not talking about anti-corrosion “mazyukaki” that contain zinc particles in their composition. This means coating the bottom, wheel arches and the entire “belly” of the car with a layer of real zinc.

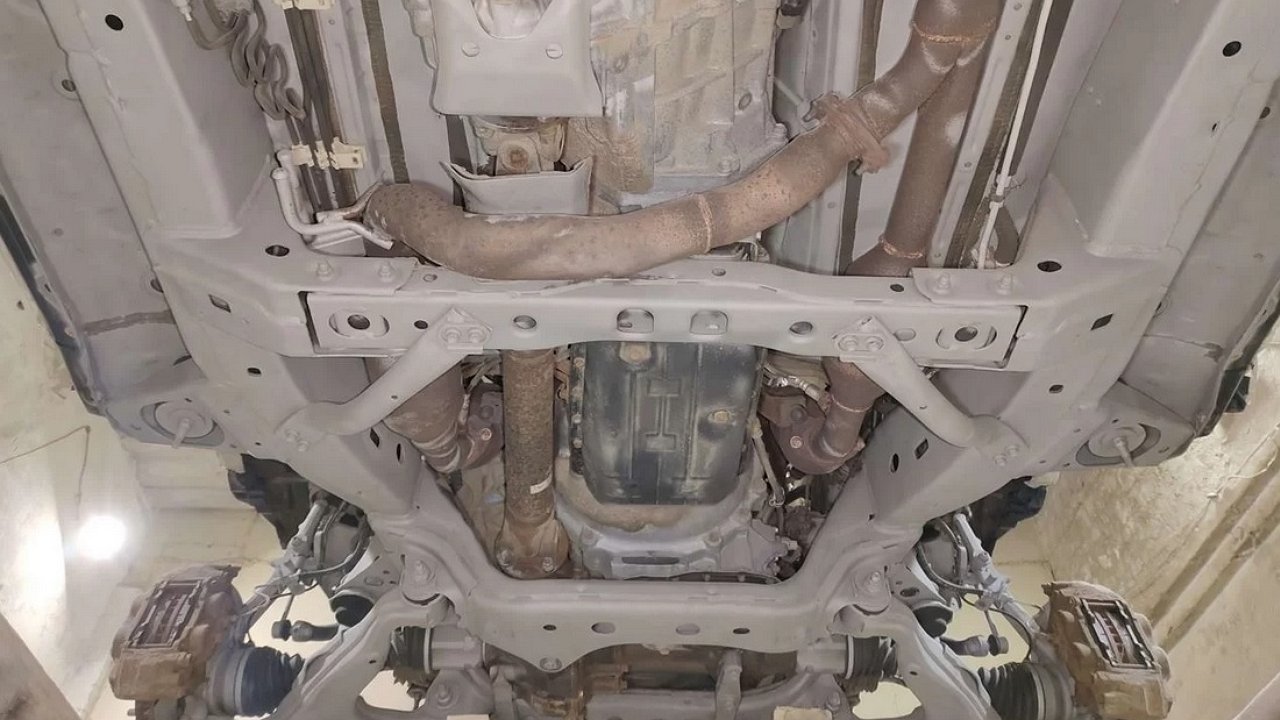

First, all surfaces intended for such treatment are thoroughly cleaned of dirt, rust and paint residues using a sandblaster. And then they are sprayed with a layer of zinc. A special device blows zinc dust from the nozzle with air heated to 500-600ºС. Zinc melts at 420ºС. Therefore, the particles in liquid form get on the metal of the body and adhere well to it. This forms a reliable protective coating. Then it is primed and sprayed and the car receives almost eternal protection against rust.

Note that such processing can be subjected not only to the “belly” of the car, but in general to the whole body, including the internal cavities of the structural elements. Discs, trailers, cooling radiators are also galvanized – whatever you want.

The galvanizing procedure is more expensive than the conventional anti-corrosion treatment. Galvanizing the bottom of a compact passenger car now costs at least 15,000 rubles, and for a jeep with a large frame, the price tag can double. But it is worth it. I paid for the galvanizing and forgot about rust forever.