According to reports, the new process uses molds filled with liquid metal instead of traditional methods such as masking, engraving and multi-step processing. 24 Channels with reference New Atlas.

How does the new technology work?

The scientists used a low-melting-point alloy known as Field’s metal, which consists of indium, bismuth and tin. This liquid metal oxidizes to form a surface oxide layer, which is then treated with a solution containing ligands, which are molecules that bind to metal ions.

Liquid with ligand penetrates into the mold due to capillary action. Following evaporation and controlled heating to 600°C, the material solidifies into nanostructures for transistors and diodes. This process also leaves behind a graphene coating that increases conductivity and prevents oxidation.

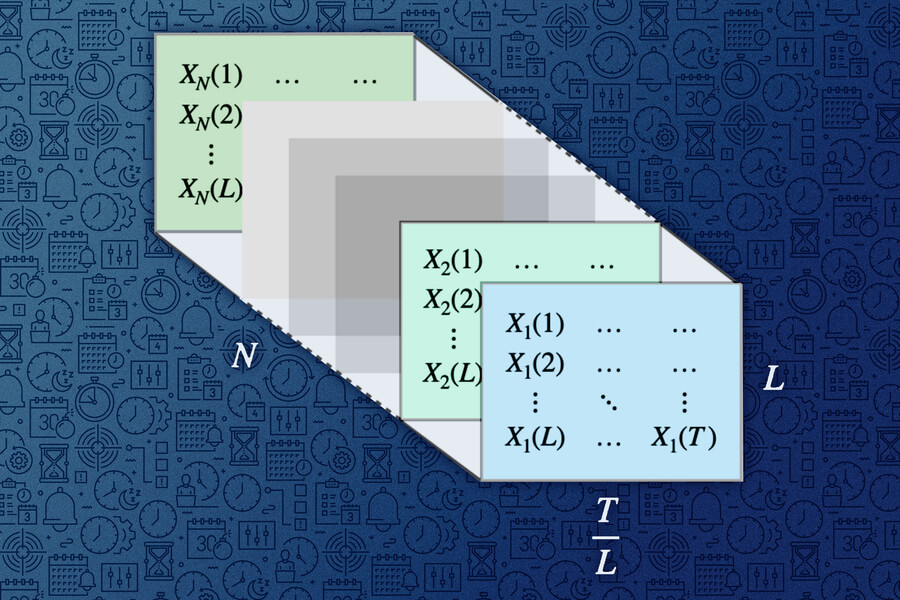

![]()

Closed channel forms have much more stable final structures / Photo: NC State University

But there is one “but”

While the method has shown impressive efficiency, it currently allows cable widths from 44nm to 1000nm; This cannot keep up with the most advanced chip manufacturing technologies such as TSMC’s 2nm process. Despite this limitation, the simplicity and speed of the new method make it suitable for many applications, especially in the fields of photonics and electronics.

Universality and effectiveness of the method

The fabricated elements are versatile, sensitive to both light and electric current, and offer possibilities for advanced photonic and electronic applications. The process leads to a reduction in the number of defective elements and significantly accelerates production rates compared to modern semiconductor manufacturing methods.

How to make processors – watch the video:

This innovative approach has the potential to complement traditional chip manufacturing methods by providing a simplified and cost-effective alternative for certain use cases that could revolutionize the entire industry.

Source: 24 Tv

I’m Maurice Knox, a professional news writer with a focus on science. I work for Div Bracket. My articles cover everything from the latest scientific breakthroughs to advances in technology and medicine. I have a passion for understanding the world around us and helping people stay informed about important developments in science and beyond.