How do engines that make tons of planes fly like a bird actually work?

- October 3, 2022

- 0

Even though the Airbus A380, one of the largest passenger aircraft in the world, has a takeoff weight of more than 500 tons, if we look at it

Even though the Airbus A380, one of the largest passenger aircraft in the world, has a takeoff weight of more than 500 tons, if we look at it

Even though the Airbus A380, one of the largest passenger aircraft in the world, has a takeoff weight of more than 500 tons, if we look at it from a distance, we see that it takes off effortlessly and glides through the air like a train. bird. Even though these planes, weighing tons, seem to defy the rules of nature, in fact we are curious about them every time we see them. How do aircraft engines work? hidden in the rules of nature that they seem to defy.

More than a hundred years have passed since mankind invented aircraft engines. Of course the first engines weren’t like that, but they still gave us the ability to fly, a quality that humans don’t naturally have. If we come to today, flying has become child’s play for us, after all, we can even go into space. If you are not an engineer: What we’re about to say can be a little confusing. but without getting bogged down in technical details, let’s take a closer look at how aircraft engines work.

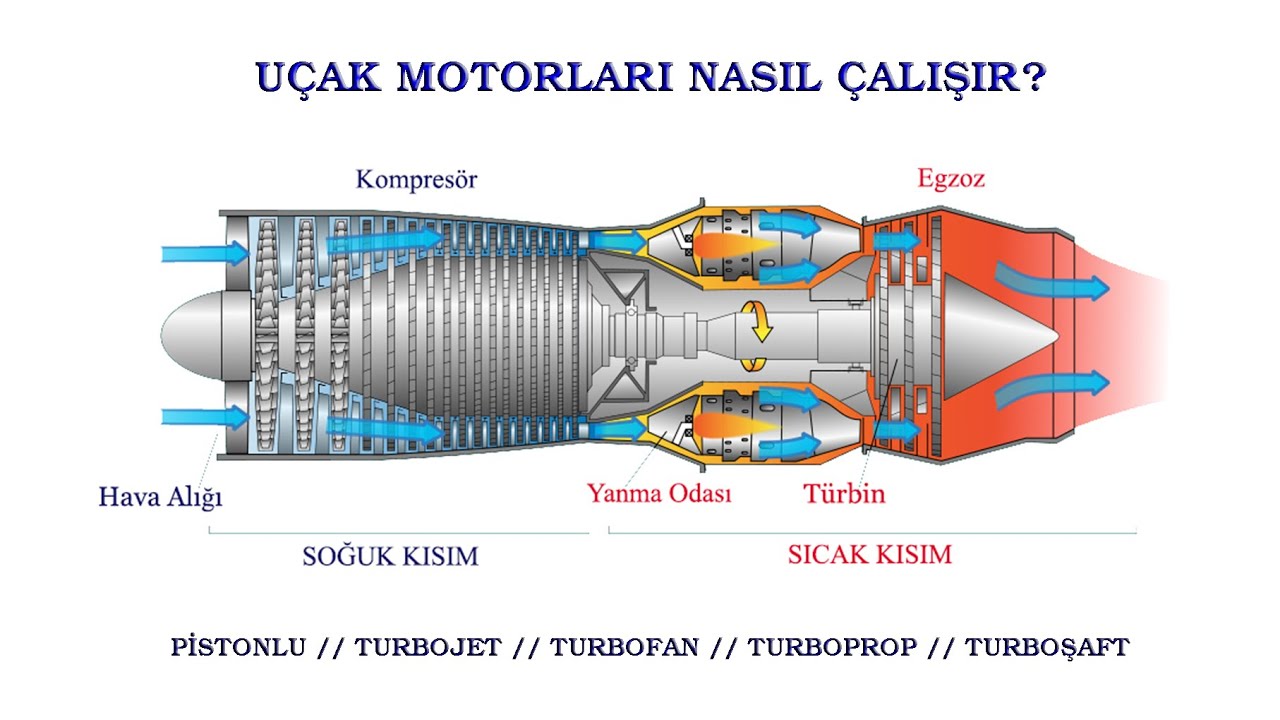

Each aircraft has engines in different numbers and functions, depending on weight and desired performance. Aircraft engines first suck in a lot of air with the help of a large fan and they compress the air they breathe. This compressed air mixes with the fuel and the fuel burns. The energy created by the effect of combustion is transferred and so an aircraft weighing tons of tons begins to move. This is how aircraft engines work in their simplest form.

Planes don’t fly because they challenge the sky, but because they work with the sky. Aircraft engines have a huge fan in the front. and this fan collects air. In the next stage of the motor, this large fan narrows and the incoming air begins to be compressed. The trapped air is then converted into energy.

Even when you open the can of soda, you realize how strong the pressure is. This is taken from the aircraft engine fan the air is so compressed it has a pressure we can’t even imagine. In the post-compression phase of the engine, the fuel comes into play because the compressed gas has to be heated. As soon as the air mixed with this gas heats up, it is expected.

The aircraft engine took air, compressed it, mixed it with fuel and burned it. Don’t underestimate the word warm up, The temperature we are talking about can rise above a thousand degrees from time to time. The gases released at such a temperature come out of the last part of the engine so strongly that the barrel weight starts to move.

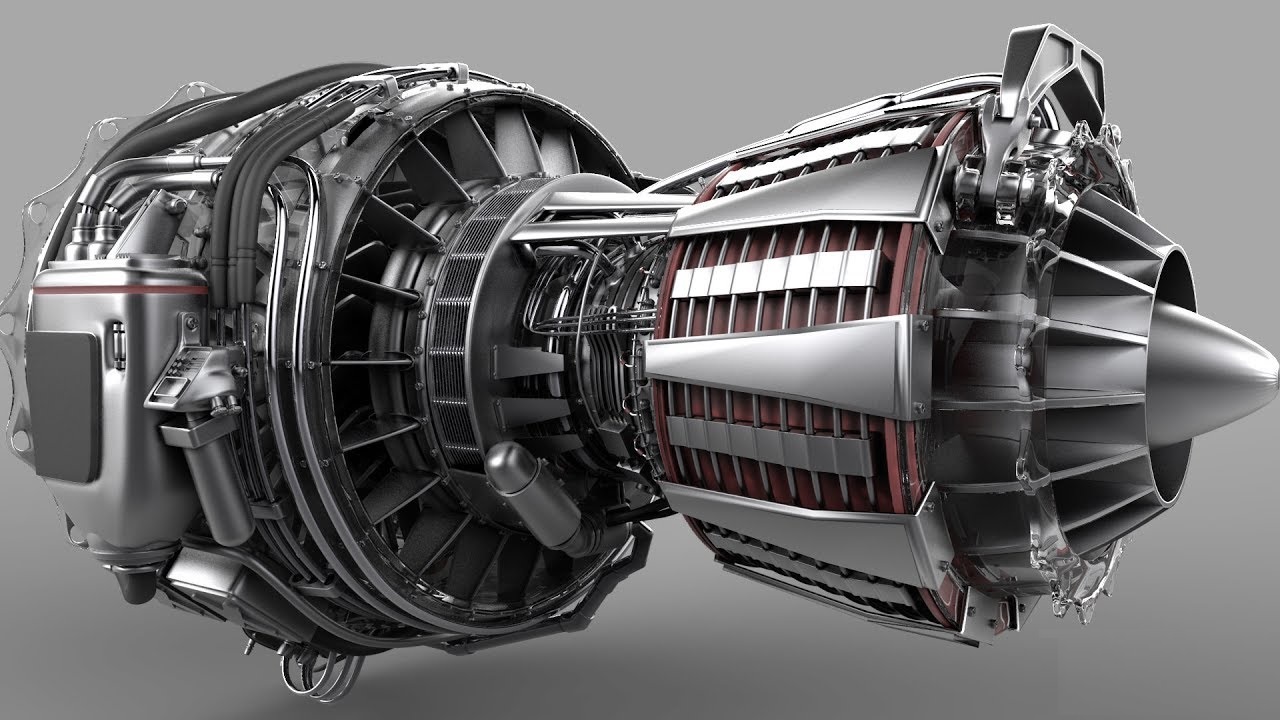

The fan is the first part of the aircraft engine and provides the air intake. This piece, which we can see from the outside, resembles a propeller made of huge blades. The thrust is provided by part of the air that is taken in by the fan. The other part of the air is transferred to the next part of the aircraft engine.

The fan, which can reach huge dimensions depending on the air ratio required for the operation of the aircraft engine, When it comes to the compressor part, it starts to narrow. Because the job of the compressor part is to compress the air drawn in by the fan. The incoming air is gradually compressed to a small volume by the compressor and a large pressure is provided.

We got a lot of air with the fan and compressed it in the compressor section and prepared it to explode. This explosion takes place in the combustion section. There are fuel nozzles and an igniter of the burner section. Fuel is mixed into the pressurized compressed air and the igniter sparks.

Of course, the energy generated by the combustion of the compressed air is not emitted directly, this energy must be used. The resulting energy is used in the turbine section. The turbine has a fan-like propeller structure. It rotates with the energy it receives and moves other parts. It transfers the remaining energy to the last part of the aircraft engine.

The last point of all this confusion, that is, the last piece of the aircraft engine is the nozzle. The nozzle is the narrowest part of the aircraft engine. because accelerating the released energy. The compressed and then burnt air coming out of the nozzle releases the necessary thrust for the aircraft.

This aircraft engine control system may have heightened the anxiety of some of our readers who are afraid of airplanes, but rest assured. These are not such simple machines. In fact, they have much less of the danger of a car engine. Accident figures confirm this.

The engineers’ main concern was the introduction of foreign objects into the fans, which were made huge for air. It could be a piece of ice, debris from the runway, or even a bird. In addition, there is an extreme power and heat. As a precaution against such hazards, the fan blades have been enhanced with a technique called laser forging. Moreover, when using a titanium material, cracking and breakage is largely prevented.

Foreign body protection is okay, but what about engine self-harm? The resulting temperature is more than a thousand degrees, and the resulting energy can fly an entire plane. Even a micron tear in an aircraft engine can grow quickly. Therefore, laser forging is not only performed on the fan section, but also on the compressor and turbine section. The parts that have undergone this process perform the necessary stretch by anticipating possible stresses. This prevents unexpected malfunctions.

You may be surprised, but the first gas-fired engine, the ancestor of aircraft engines It was invented in 250 BC by Heron of Alexandria. The first primitive rockets with a similar system were used by the Chinese in 1232. Fireworks, the ancestors of these rockets, have been used since 3000 BC.

The theorem of the amount of motion, put forward by the English physicist Isaac Newton in 1687, opened the doors of a new era. The first gas turbine was designed in 1791 by John Baber. In 1911, Alfred Buchi developed turbochargers and this system was used in aircraft in 1916.

In 1930 Frank Whittle combined the gas turbine and diffuser, and in 1936 he patented the turbojet for this system. The first true jet engine was developed in 1937 by Hans von Ohain. It worked successfully in 1941. Today, there are many types of aircraft engines, such as turbojet, turbofan, turboprop, turboshaft and ramjet.

The one who manages to take off tons of planes like a bird. how airplane engines work We answered the question and tried to get to know this system a little better without drowning in technicalities. You can share your thoughts on the topic in the comments.

Source: Web Tekno

I’m Maurice Knox, a professional news writer with a focus on science. I work for Div Bracket. My articles cover everything from the latest scientific breakthroughs to advances in technology and medicine. I have a passion for understanding the world around us and helping people stay informed about important developments in science and beyond.