In this way, a car cannot be made quickly, but the problems of repair and maintenance can be closed. And, apparently, it was this path that was chosen “at the top”: for a while or forever they will not predict. However, remember that in Russia there is nothing more permanent than temporary. The example of the Mir station is contagious.

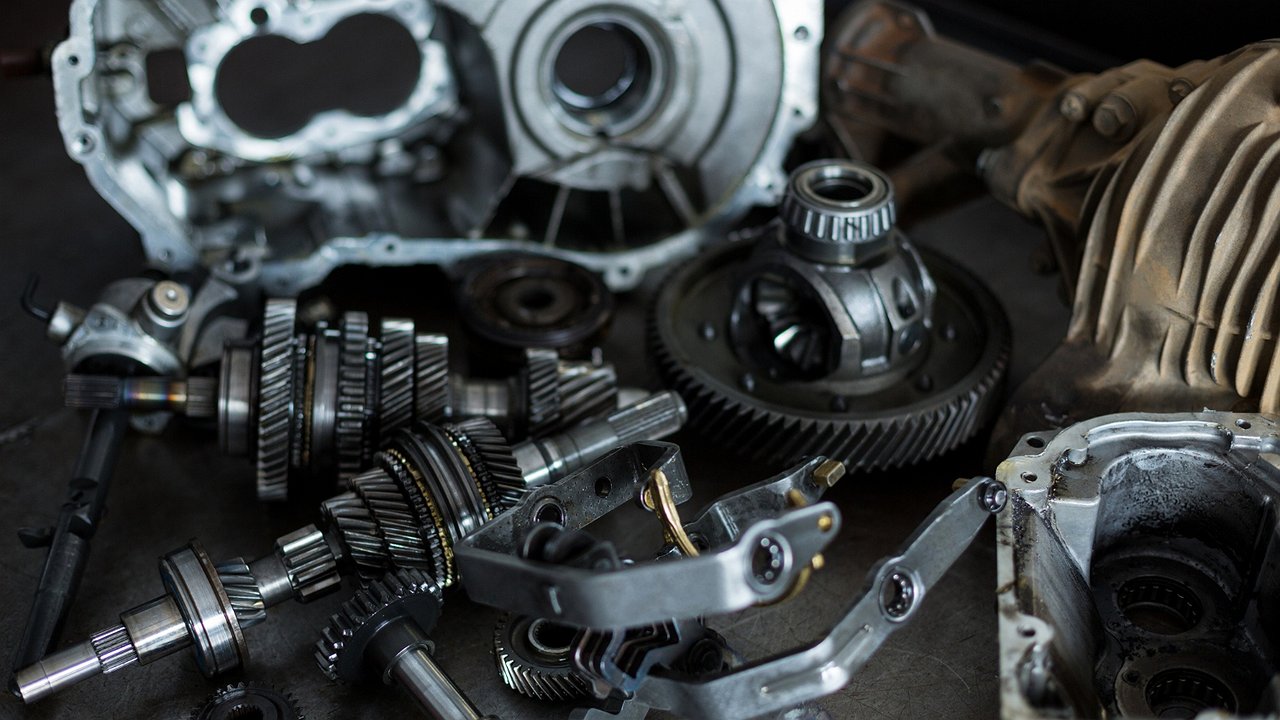

Novokuznetsk scientists have already released a 3D scanner that allows you to digitize every detail. The device is able not only to create a super-accurate model of absolutely any unit and assembly, but also to create a map of anomalies, as well as to study the composition of the object. Simply put, such equipment allows you to quickly prepare the necessary technical documentation and start production of almost any spare part. This is called reverse engineering – we disassemble and study the device to copy it later.

Such a device costs only 395,000 rubles – cheaper than a decent lathe, approximately on the level of a Chinese laser CNC. Therefore, purely hypothetically, the development of Novokuznetsk techies is able to launch an entire field of industrial espionage in Russia, based on small enterprises to garage workshops. The news that some 500 such scanners have already been ordered – both for private companies and defense companies – is not surprising. After all, with the “gadget” you can reduce years of research and development to weeks.

Indeed, there is no need to reinvent the wheel. Yes, and once – the country needs spare parts. And not tomorrow, but yesterday.