How a simple clamp can ‘kill’ a turbine when repairing a car

- August 31, 2023

- 0

Many motorists have begun to seriously save money, and therefore they try to do the simplest work of replacing consumables on their own. However, they often make small

Many motorists have begun to seriously save money, and therefore they try to do the simplest work of replacing consumables on their own. However, they often make small

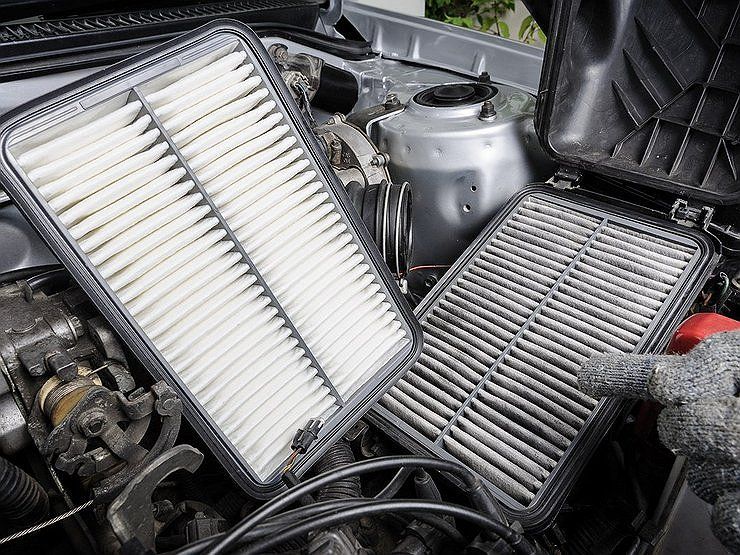

The process of replacing filters, engine oil and brake pads is quite simple on most cars, so the mates save on service and do everything themselves. However, sometimes it happens that after updating the air filter, a car with a turbo engine simply refuses to drive. This can happen at full speed on the track. The engine barely gains momentum, barely turns – in general, it is clear that they “arrived”. It feels like the ‘iron horse’ is attached to a heavy wagon, and the Check Engine also lights up.

As a rule, when faced with such a nuisance, they come up with various reasons. For example, that the gas station is responsible for interruptions, where the fuel (petrol or diesel) ‘gets stuck’, or a low-quality ‘bleeder’ that has just been replaced. And be that as it may, you should definitely go to the gas station.

But after visiting the service it doesn’t get any better. When making the diagnosis, a wreath of errors appears with a number of sensors and even injectors. This is where the boost sensor goes “crazy” and blasts. Other masters, if the car is used, blame the old wiring. For example, the contacts disappear due to the oxides.

Of course, they immediately climb to check the health of the sensors. And it turns out that they are all normal. Where should you look? to the inlet channel. It’s covered in oil, because when the intercooler flows, the turbine fails. But what was the reason?

And it lies in the turbine impeller, which is simply worn out. The fault is the foreign object that has blocked the impeller. This same object often becomes part of the clamp of the pipe that connects the air box to the DMRV (mass air flow sensor) and to the turbine intake.

Sometimes drivers are inattentive when replacing the air filter and clamps. Here are the parts and go to the wrong place. The result is the replacement of the “snail”. Now it costs more than 100,000 rubles. And you’re lucky if a piece of metal doesn’t fly into the intake manifold. Otherwise things will get really bad.

And in summary, we note that it is better for absent-minded car owners to immediately go to the service for scheduled maintenance than to spend a lot of money later to replace the units.

The process of replacing filters, engine oil and brake pads is quite simple on most cars, so the mates save on service and do everything themselves. However, sometimes it happens that after updating the air filter, a car with a turbo engine simply refuses to drive. This can happen at full speed on the track. The engine barely gains momentum, barely turns – in general, it is clear that they “arrived”. It feels like the ‘iron horse’ is attached to a heavy wagon, and the Check Engine also lights up.

As a rule, when faced with such a nuisance, they come up with various reasons. For example, that the gas station is responsible for interruptions, where the fuel (petrol or diesel) ‘gets stuck’, or a low-quality ‘bleeder’ that has just been replaced. And be that as it may, you should definitely go to the gas station.

But after visiting the service it doesn’t get any better. When making the diagnosis, a wreath of errors appears with a number of sensors and even injectors. This is where the boost sensor goes “crazy” and blasts. Other masters, if the car is used, blame the old wiring. For example, the contacts disappear due to the oxides.

Of course, they immediately climb to check the health of the sensors. And it turns out that they are all normal. Where should you look? to the inlet channel. It’s covered in oil, because when the intercooler flows, the turbine fails. But what was the reason?

And it lies in the turbine impeller, which is simply worn out. The fault is the foreign object that has blocked the impeller. This same object often becomes part of the clamp of the pipe that connects the air box to the DMRV (mass air flow sensor) and to the turbine intake.

Sometimes drivers are inattentive when replacing the air filter and clamps. Here are the parts and go to the wrong place. The result is the replacement of the “snail”. Now it costs more than 100,000 rubles. And you’re lucky if a piece of metal doesn’t fly into the intake manifold. Otherwise things will get really bad.

And in summary, we note that it is better for absent-minded car owners to immediately go to the service for scheduled maintenance than to spend a lot of money later to replace the units.

Source: Avto Vzglyad

Donald Salinas is an experienced automobile journalist and writer for Div Bracket. He brings his readers the latest news and developments from the world of automobiles, offering a unique and knowledgeable perspective on the latest trends and innovations in the automotive industry.