Domestic manufacturers plan to increase production of electric cars by as much as 9 times this year. In total, they should produce more than 18,500 units and by 2025, the numbers will exceed 52,000, the Avtostat agency reports. But mostly we are talking about assembling Chinese models.

If we talk about our own developments, then for their production it can be difficult at first to buy components in the domestic market, says Pablo Iturralde, director of the Advanced Engineering School of Electric Transport at Moscow Poly.

According to the expert, there is an opinion that it is easier to create such a type of transport. In fact, it is not about simplicity, but about accessibility. Now the country does not have its own production of modern internal combustion engines. And the situation with electric motors is no better. But from a technological point of view, it is much easier to arrange the assembly of the latter than ICE. If you can solve the problem with components, then mass production is quite realistic.

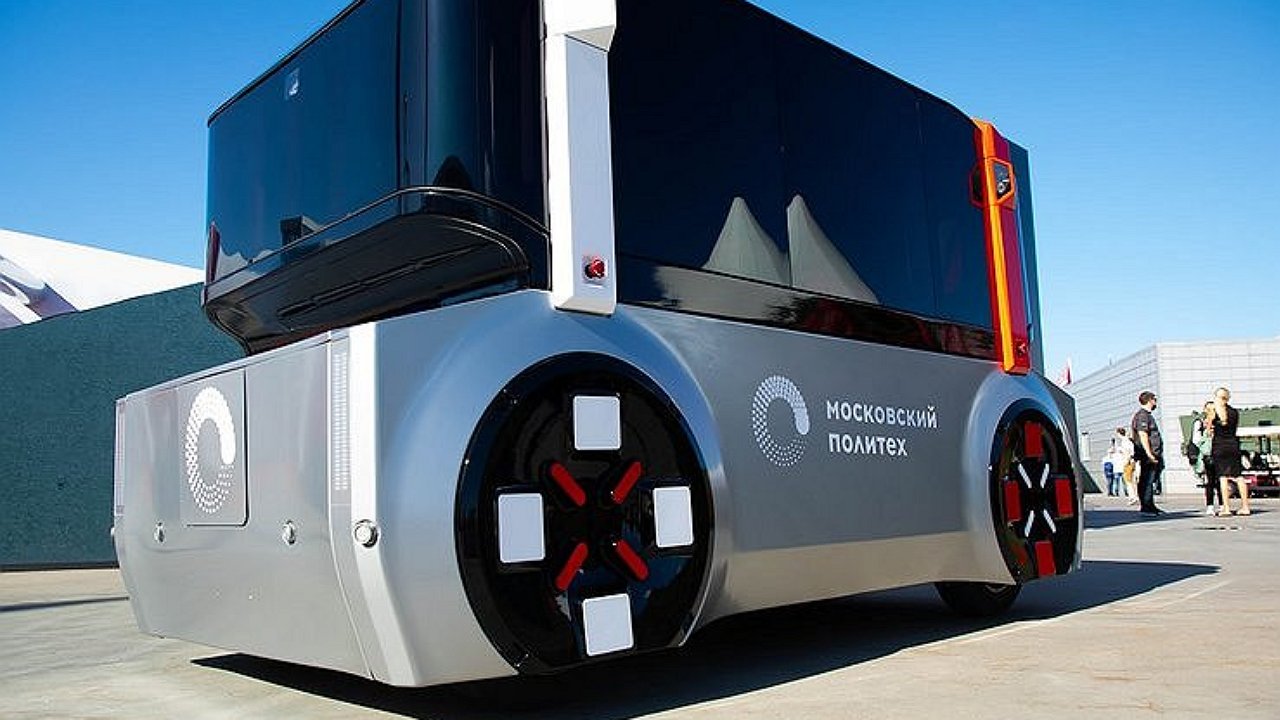

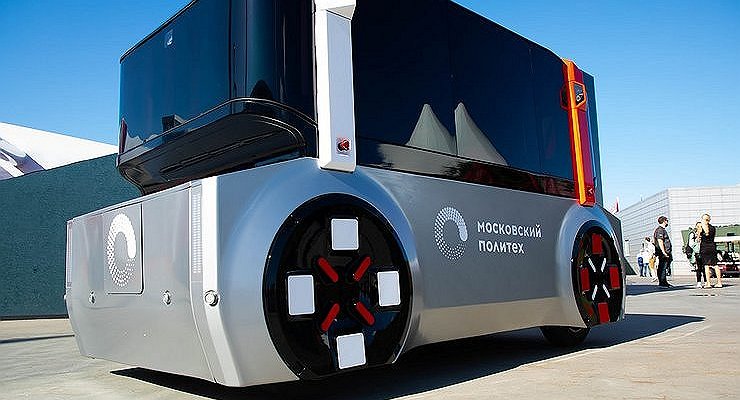

By that time, household solutions will also be on time. For example, the Moscow Poly is working on the innovative platform L−7 as part of the strategic project “Affordable electric car”. It will form the basis of a 4-seater electric car.

It remains only to understand who will buy such “iron horses”. As the results of a recent study from the SuperJob resource show, 7 out of 10 Russians are not ready to abandon a car with an internal combustion engine in favor of a newfangled electric train. In comparison, in 2021, the percentage of those who did not trust “battery” transport was lower – 64%.