Why are ships round when almost all windows are square?

- June 10, 2023

- 0

This situation random design difference You would think so, but the situation is very different than expected. Because the rounded or angular windows on ships affect these ships

This situation random design difference You would think so, but the situation is very different than expected. Because the rounded or angular windows on ships affect these ships

This situation random design difference You would think so, but the situation is very different than expected. Because the rounded or angular windows on ships affect these ships in many ways, from life safety to durability.

Unlike these window sizes we know and use What are the advantages of round? Let’s take a closer look at what it is.

The windows used on airplanes in the 1950s were different from what they are today. it was angular, not round. The reason why engineers started designing them around was the successive accidents at the time.

While these accidents were initially thought to be pilot error, they were actually caused by design flaws and the problem was: sat in the plane’s angular windows. During the flight, these windows were cracked and the fuselage of the aircraft was damaged at these points.

After all this, airplane windows, started to be designed in round and oval shape and it remains the same form today.

Airplanes need high altitudes for a more comfortable flight, and this way drift and turbulence are minimized. However, there are some drawbacks to flying at such high altitudes, and the first is that the atmospheric pressure is very low at high altitudes.

As the aircraft ascends, the pressures inside the cabin and outside the cabin differ, so adjusting the cabin’s interior pressure is essential for crew survival. Ideally, this pressure should be distributed as evenly as possible throughout the aircraft. but windows in certain parts of the body divert pressure to the sides.

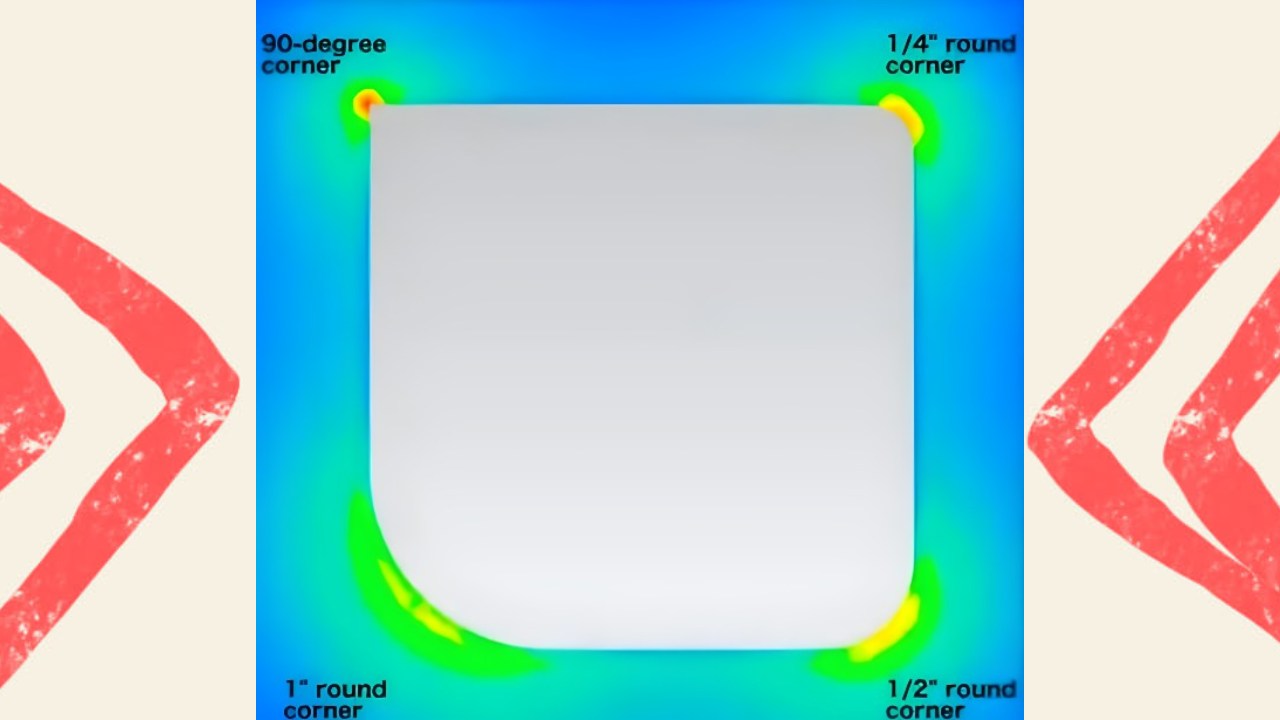

The reason for this is that the force per unit area on the acute angles increases exponentially. So are the yellow, green and red colors in the corners of the photo the magnitude of the stress at those points reflects.

This object, on which force is applied in aircraft and ships, Stacks in the corners are colored red if they are high.Although the stretchability of the parts that are not sharp and have different ovalities is low, they are expressed in yellow and green colors.

These ovals are caused by the air pressure in the aircraft or ship, distributed in the form of rounded curves over the entire surface and aims to prevent damage and accidents as much as possible.

The building materials that make up wooden ships, and especially wet wood, are reflected in the material. was very resistant to fatigue stress and the first ships were made from this raw material. In the period when wooden ships were popular, you could quite often come across rectangular and square windows.

However, by the end of the 19th century, steel-hulled merchant ships became common, followed by warships. Over time, engineers realized that these angular windows were a design flaw, and Saying goodbye to wooden materials, square and rectangular windows came to an end.

These round windows were actually created during the movement of ships at sea. resistance to high pressure and tensile forces offers. In addition, round shapes on ships take up much less space than angular windows and help to use the limited space on board much more efficiently.

For all these reasons, in many architectural designs that need to be resistant and robust, oval and round shapes as much as possible, avoiding sharp corners desirable. Again, round shapes are much more resistant to deformation, whether it’s an aircraft or a marine vehicle, and it’s much easier to shape the glass into a round shape.

Source: Web Tekno

Ashley Johnson is a science writer for “Div Bracket”. With a background in the natural sciences and a passion for exploring the mysteries of the universe, she provides in-depth coverage of the latest scientific developments.